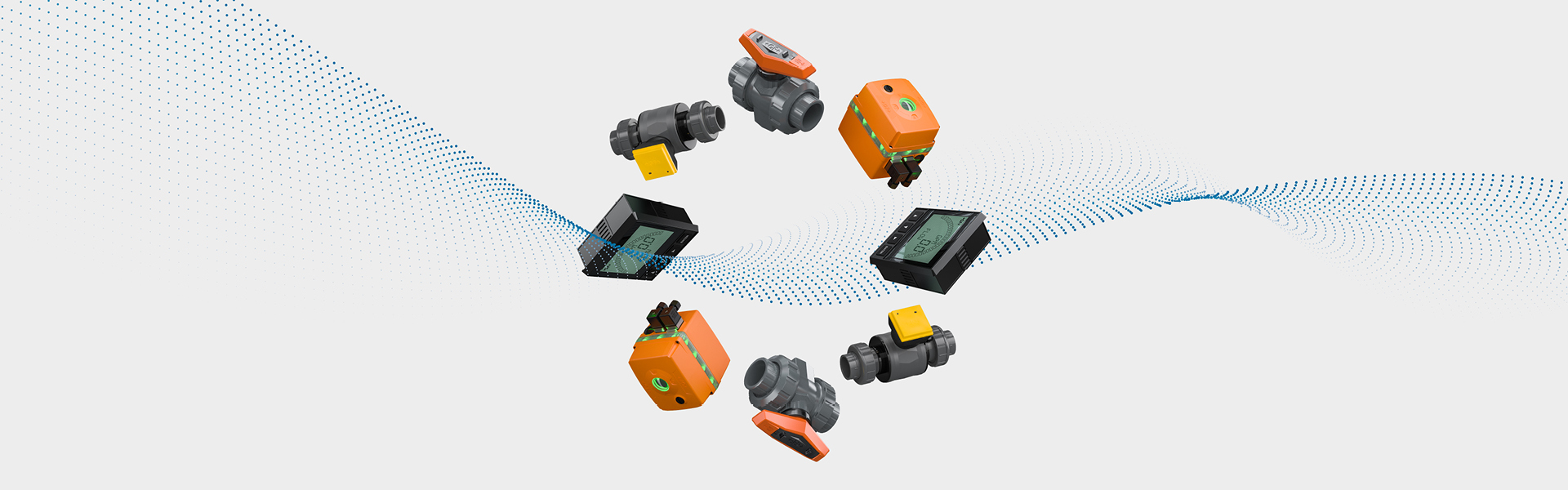

Achieve High Purity Through Polymer Piping Systems

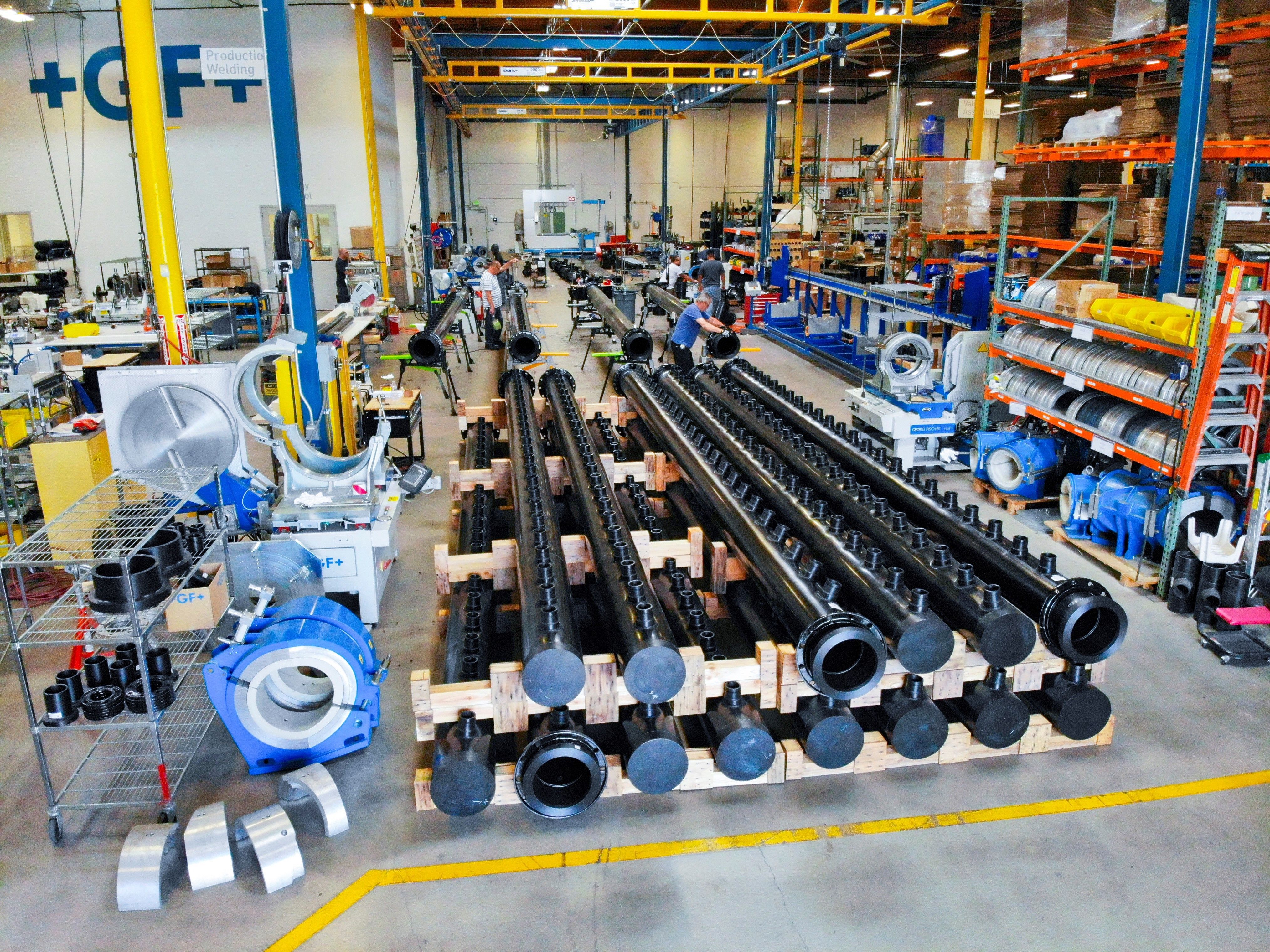

Green hydrogen is produced by harnessing clean energy from renewable sources, such as solar, wind and hydropower, and then employing electrolysis to split water into two hydrogen atoms and one oxygen atom. Water intended for electrolysis typically undergoes purification using standard reverse osmosis processes, often necessitating additional deionization steps to eliminate any remaining ions. We contribute to these applications with our solutions in the transportation of deionized water to scale up production while simultaneously reducing the capital cost of green hydrogen overall.