From Waste to Worth: Elevate Water Reuse

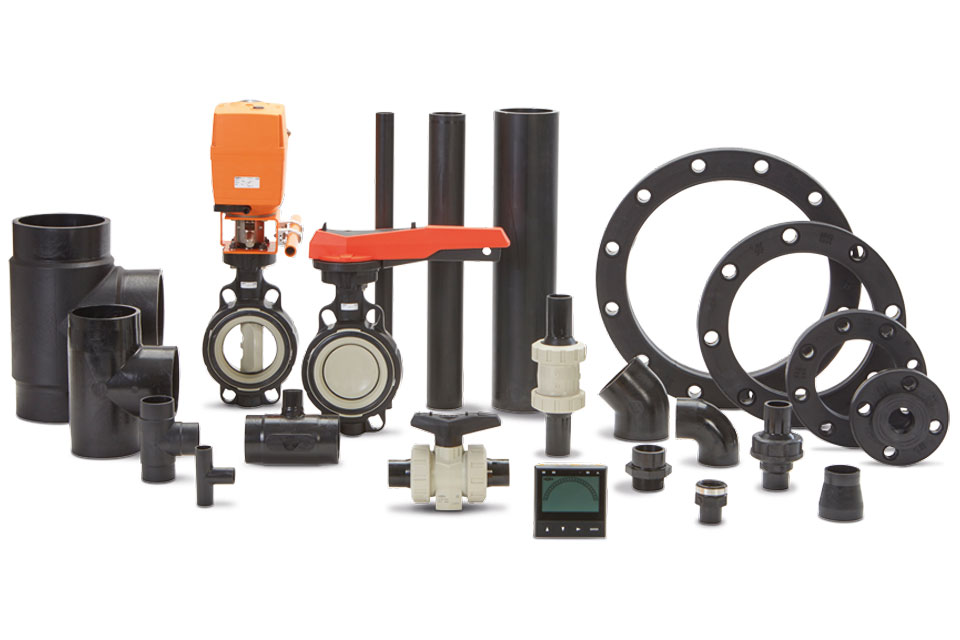

Wastewater treatment is the process of removing contaminants from water used in homes, industries, and businesses to make it safe for discharge or reuse, ensuring environmental protection and public health. The industry faces several challenges, such as corrosion, chemical resistance, maintenance, and efficiency. Thermoplastic piping systems effectively address these. Unlike metal, thermoplastic solutions are resistant to corrosion and aggressive chemicals while offering a longer lifespan and reduced maintenance. Their durability and smooth interiors enhance flow efficiency and reduce energy costs. Lightweight and easy to install, they lower labor costs and adapt to various conditions, offering flexible solutions.