Advanced Solutions to Fight Water Scarcity

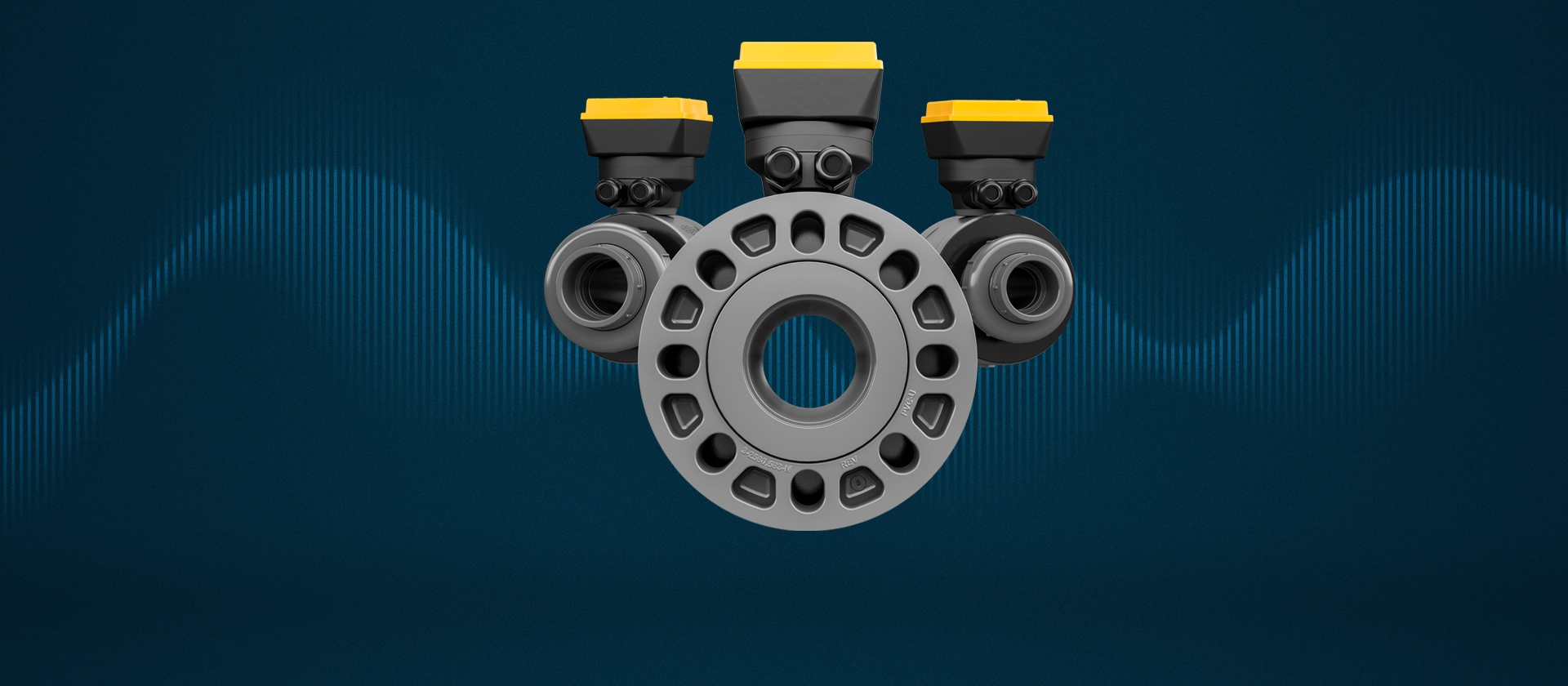

The water treatment market faces several critical issues, with increasing urbanization and global warming resulting in one of the biggest concerns, namely water scarcity. Also, regulations on water discharge are getting stricter, commodity prices are rising, and infrastructure is aging in the developed world. Furthermore, providers are under pressure to keep up with digitization, aiming to have a competitive advantage in the industry of the future. Our comprehensive product portfolio includes state-of-the-art and interoperable valve and measurement solutions for Process Automation, as well as pipes, fittings, and jointing technology, offering holistic solutions across the whole water cycle.