Ensuring Freshness and Quality in Every Bake

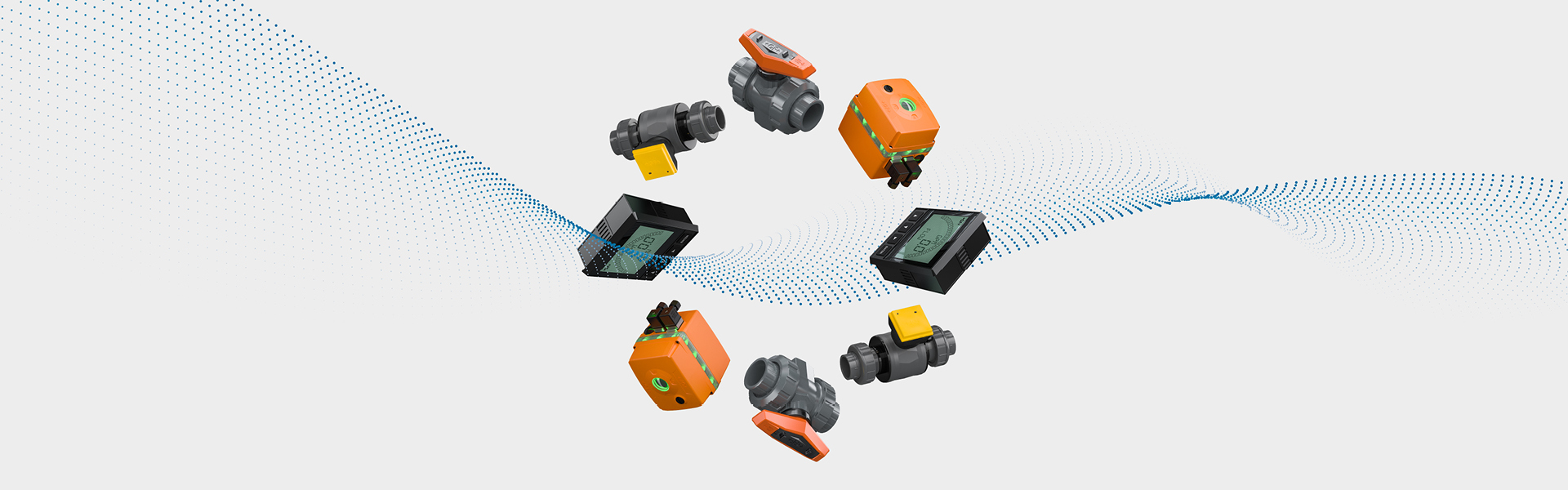

Bakeries face unique challenges in maintaining precise temperatures and hygiene standards essential for producing high-quality baked goods. GF Piping Systems provides corrosion-free, pre-insulated piping solutions designed to optimize cooling and heating processes, ensuring consistent temperature control, and preventing contamination. Our innovative systems reduce energy consumption and maintenance costs, enhancing operational efficiency. With GF Piping Systems, bakeries can achieve the highest standards of product quality and safety, ensuring freshness and consistency in every bake.