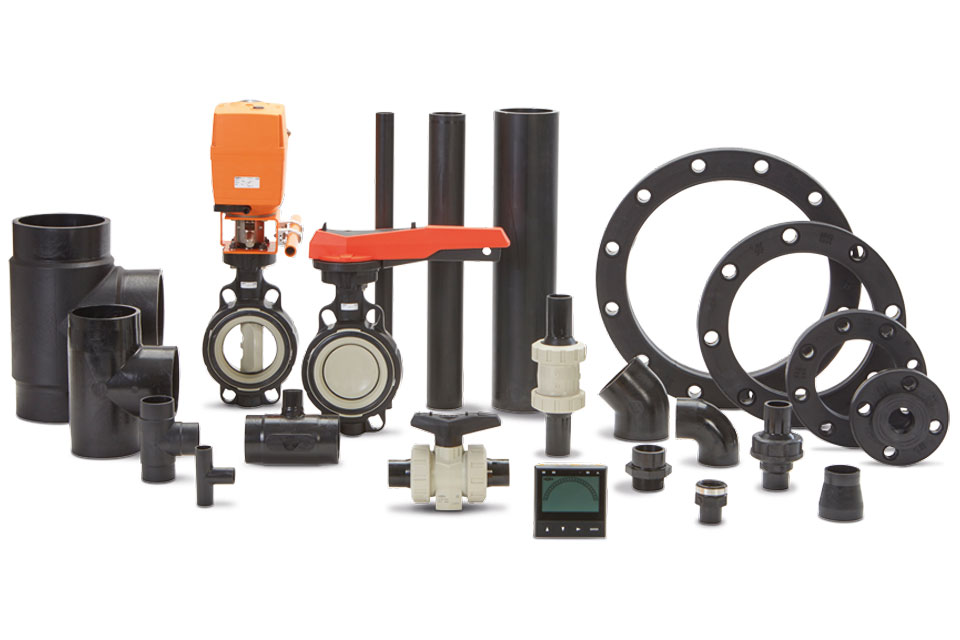

From Ore to More

Mineral processing ensures that the extracted material is more concentrated and suitable for further extractive metallurgy procedures. The aggressive environment of mining sites presents a particular challenge for piping systems. Depending on the application, different materials for pipes, fittings and valves combined with the right instrumentation are suitable to transport sulphuric acid, sodium cyanide, hydrogenchloride, sodium hydroxide, carboxymethyl cellulose and other hazardous liquids and other hazardous liquids. GF Piping Systems' solutions are the right fit due to their excellent chemical resistance, reliability, temperature resistance and durabilitiy.