Application

Optimizing Ion Exchange Systems with Thermoplastic Piping Systems

Ion exchange is the exchange of ions between two electrolytes or between an electrolyte solution and a complex. This process is widely used for purification, separation, and decontamination of aqueous and other ion-containing solutions. In a resin ion exchanger, a resin containing positive or negative ions absorbs unwanted ions into the water and transfers them to a regenerating solution. Other ion transfer methods, like electrodialysis, use an electrical field to push positive or negative ions through semi-permeable membranes, collecting pure water.

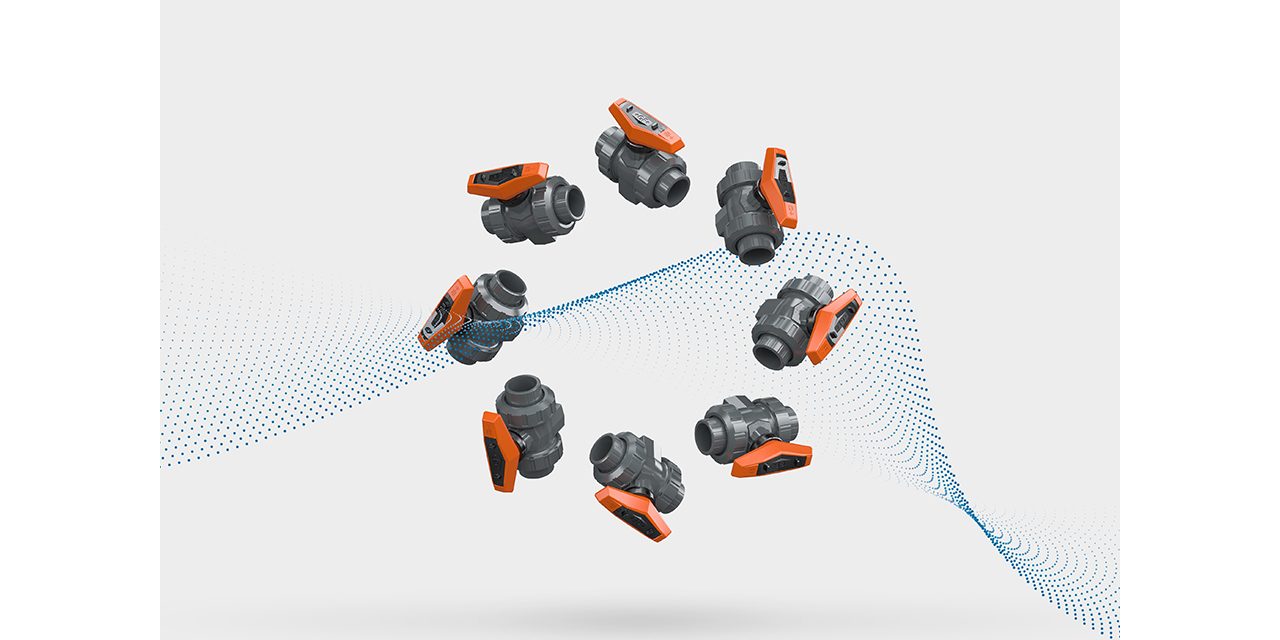

Thermoplastic piping systems enhance ion exchange units by superiorly resisting corrosion, chemicals, and high temperatures. Unlike metal, thermoplastic components help to ensure long-term durability and reduce maintenance costs. Their lightweight nature simplifies installation and reduces labor expenses. By integrating thermoplastic piping systems, industries can improve efficiency, flexibility, reliability, and cost-effectiveness in their ion exchange processes, ensuring optimal performance.

Success Story: Biological Technology Ion Exchange Project

OMZ Tianjin, China

Explore how over 5,000 valves across 7 parallel ion exchange systems contributed to the success of an L-lactic acid super project. Learn how our high-performance diaphragm and ball valves boosted resin utilization efficiency by over 30%, while reducing wastewater discharge by 40%.

Please accept all cookies to view the youtube video content.

FAQs

What measurement parameters are vital for high-quality ion exchange systems?

Vital measurement parameters for high-quality ion exchange systems include pH, conductivity, and flow.

pH is crucial as it affects the ion exchange capacity and resin stability, ensuring optimal removal of unwanted ions. Conductivity measures the ion concentration in the water, indicating the system's effectiveness in ion removal and water purity. Flow rate impacts contact time between water and the resin; maintaining proper flow ensures efficient ion exchange and prevents resin channeling or fouling, enhancing overall system performance.

What is the difference between cation exchange systems and anion exchange systems in ion exchange applications?

Cation exchange systems and anion exchange systems differ primarily in the type of ions they target and exchange. Cation exchange systems remove positively charged ions (cations) such as calcium and magnesium, often using strong or weak acid cation resins. Anion exchange systems, on the other hand, remove negatively charged ions (anions) like chloride and sulfate, utilizing strong or weak base anion resins.

What are typical challenges of Ion Exchange systems and how can thermoplastic piping systems help to solve them?

Typical challenges of ion exchange systems include corrosion, chemical resistance, and mechanical wear, particularly in valves, actuation, and solutions for process automation. Thermoplastic piping systems address these issues by offering superior resistance to corrosive chemicals and harsh environments, extending valve life and reliability. Their smooth surfaces reduce scaling and fouling, improving process efficiency. Lightweight thermoplastics ease the integration of automated actuators and sensors, enhancing control and reducing maintenance downtime, ensuring consistent system performance.