pH-level in Control

Neutralization is a vital process for adjusting the pH of various substances to a neutral range, typically between 6.5 and 8.5, ensuring they are safe for further use or discharge. This process involves adding acidic or alkaline agents, such as sulfuric acid or caustic soda, to correct pH levels. Effective neutralization prevents issues like corrosion, scaling, and environmental harm.

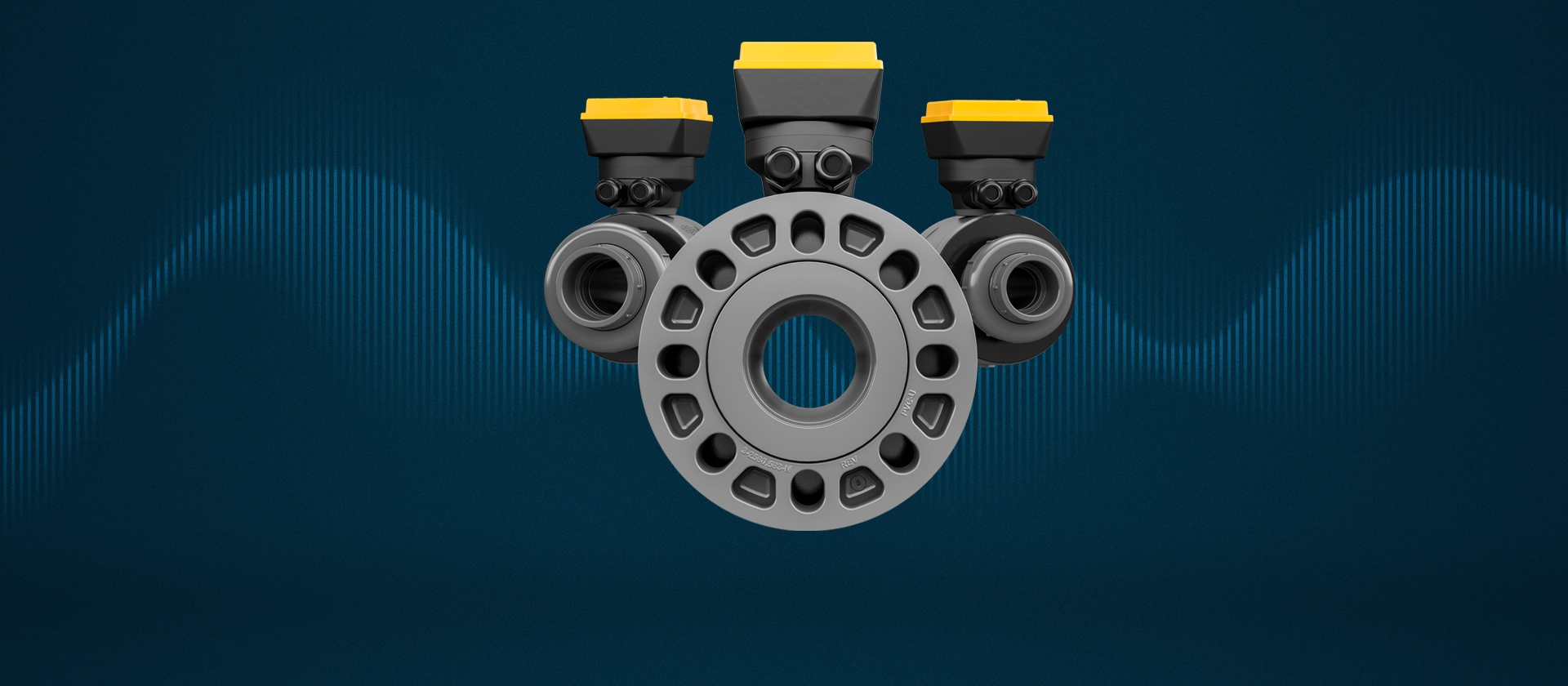

Achieving precise pH regulation requires real-time monitoring and careful control, especially when dealing with substances that will be released into public systems or natural environments. Thermoplastic piping systems play a key role in enhancing this process, offering smooth, corrosion-resistant surfaces that reduce friction and improve efficiency and system longevity.

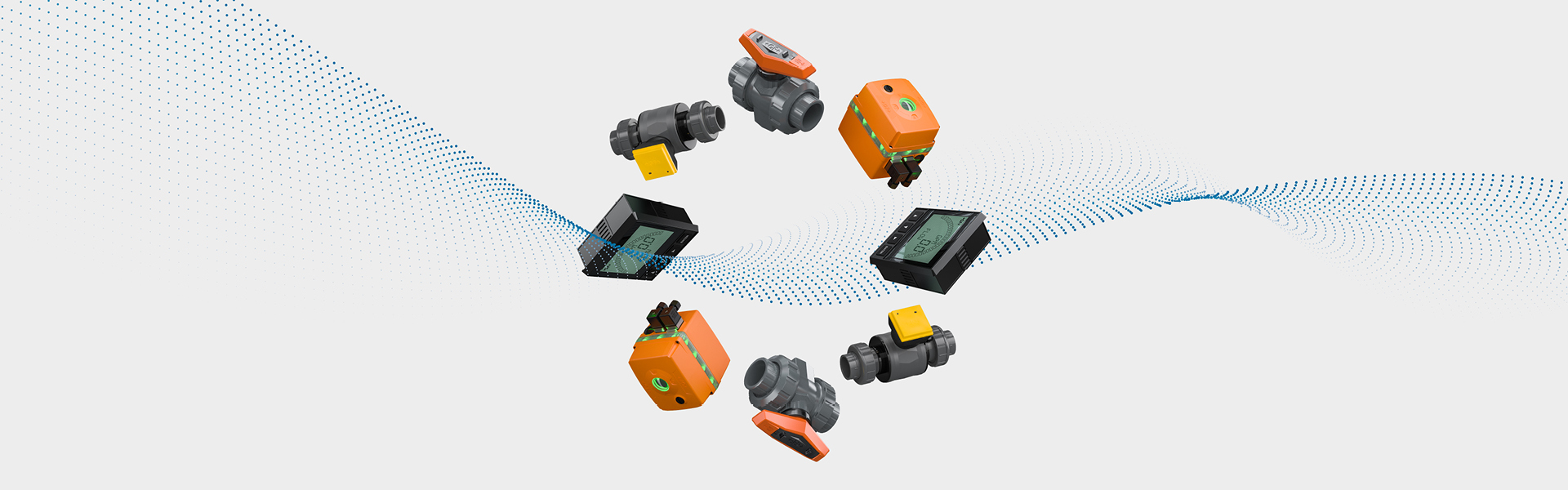

The use of state-of-the-art instrumentation makes the neutralization process reliable, cost-effective, and compliant with environmental regulations, optimizing overall system performance.