Polymer Piping Supports Electrolysers' Efficiency and Longevity

PEM (Proton Exchange Membrane) electrolyser utilizes a proton exchange membrane and a solid polymer electrolyte to efficiently split water into hydrogen and oxygen. When a current is applied, hydrogen protons pass through the membrane, forming hydrogen gas on the cathode side. The temperature range for PEM electrolyses typically spans from 50°C to 80°C, with operating pressures ranging from ambient pressure up to 30 bar.

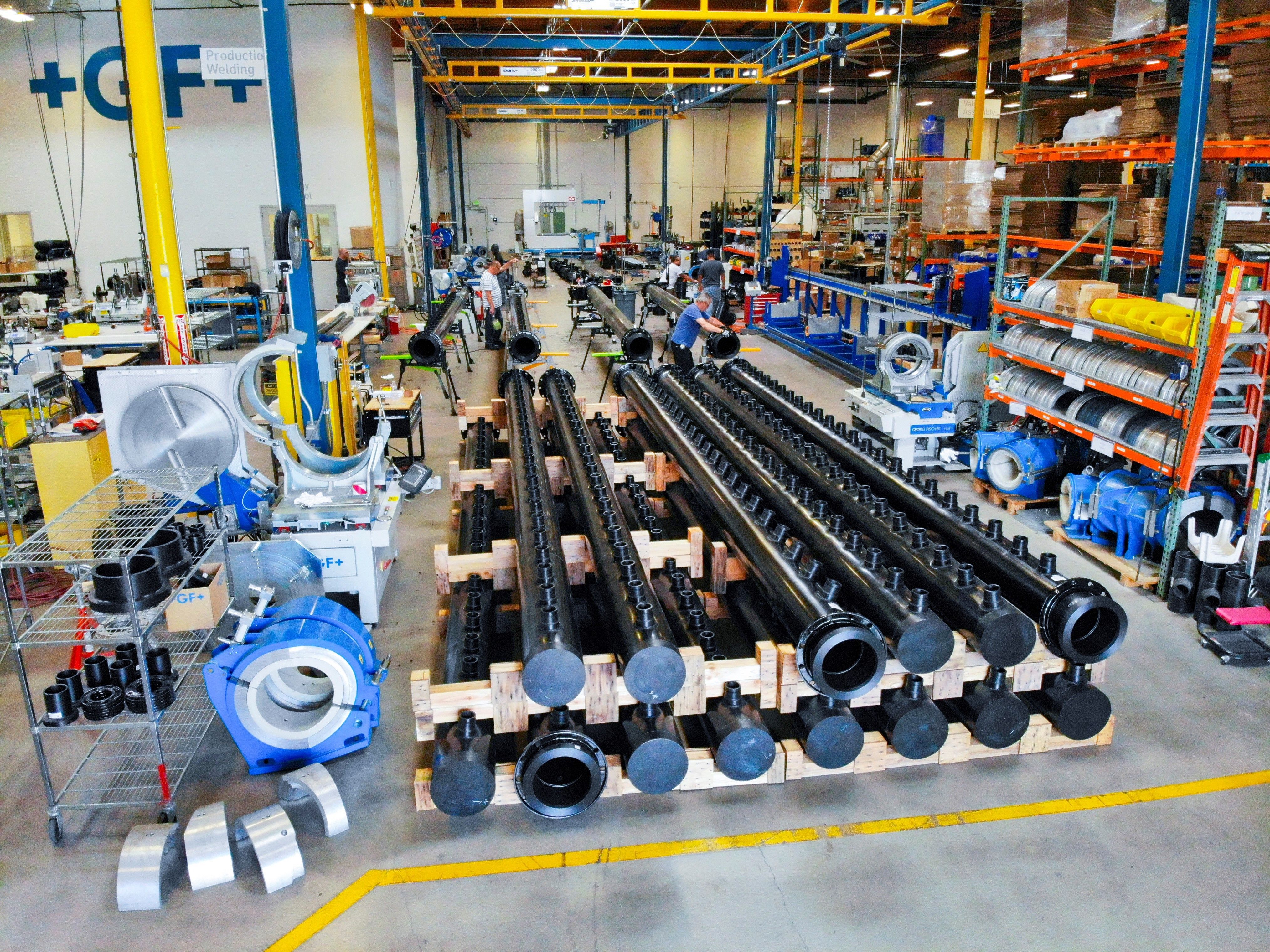

The efficiency and lifespan of PEM electrolysis systems are highly dependent on the quality of the input water. High-purity water is essential to prevent membrane contamination and ensure optimal performance. Polypropylene PP-H is an ideal material used in these systems due to its excellent chemical resistance, mechanical strength, and ability to maintain integrity under the specific temperature and pressure conditions of PEM electrolysis. Ensuring the purity of water input helps maximize the efficiency and longevity of the electrolyser, making it a critical factor in the overall effectiveness of hydrogen production.