Chemical-Resistant Flow Solutions for Reliable Operations

In an alkaline electrolyser, a potassium hydroxide (KOH) solution is used to split water into hydrogen and oxygen. When electricity is applied, water molecules break into hydrogen ions (H+) and hydroxide ions (OH-) at the anode. Hydrogen ions combine with electrons at the cathode to form hydrogen gas, while oxygen gas is produced at the anode. This process, facilitated by KOH, creates hydrogen and oxygen.

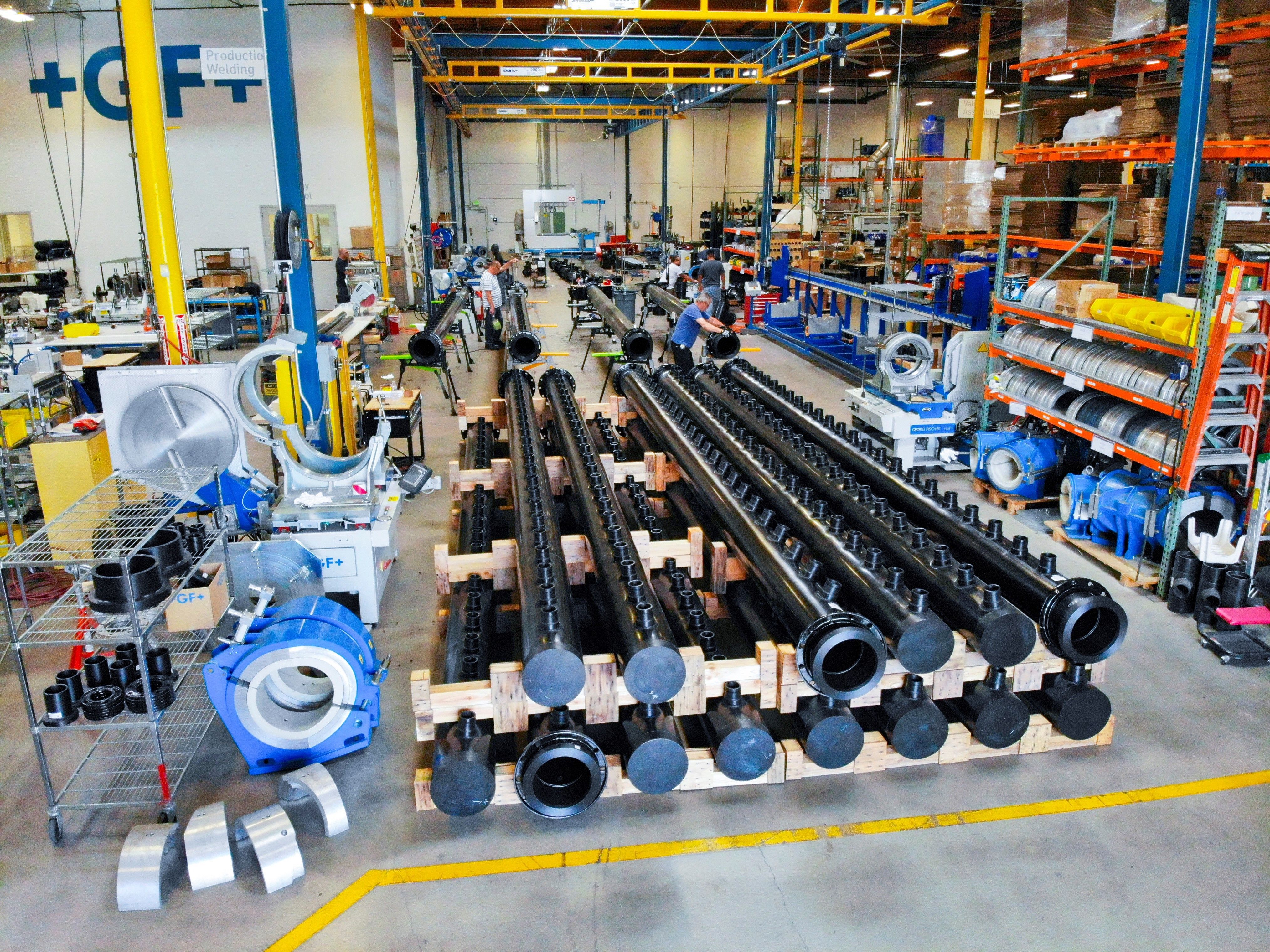

Polymer piping systems transport various liquids and gases to provide electrolyte and gas cooling, feed, and process water. To enhance the accessibility of green hydrogen, we advocate for expanding production to help mitigate costs as it progresses through the value chain.