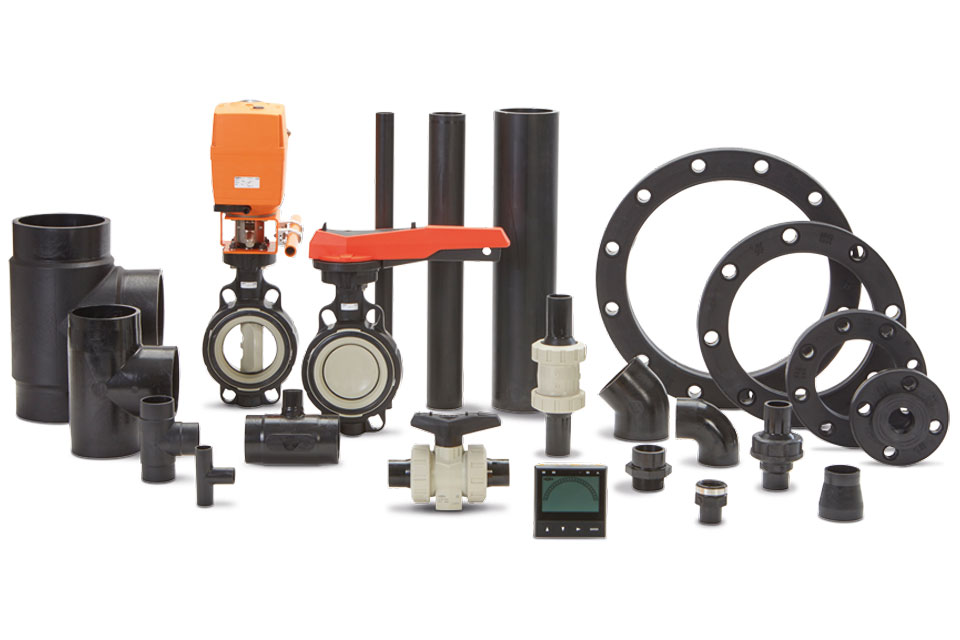

Reliable in the Largest Dimensions

From reservoirs to treatment plants, we ensure seamless water flow across the region. Our experience and know-how in building, operating, and maintaining large-dimensioned piping systems enable us to create the right solutions for your varied installations in water transport applications. Typical diameters range from d355 upwards, and the pressure generally falls within 0 to 16 bars. Beyond water, we also specialize in gas transportation over long distances—from production regions to consumption areas. These systems typically fall within the range of d225mm upwards, with a pressure usually ranging from 4 to 10 bars. The transport of gas can be a challenging task, so a safe and reliable connection is the key factor.