Cool Power: Polymer Solutions for Optimal PEM Fuel Cell Performance

In Proton-Exchange-Membrane fuel cells, managing the heat generated from hydrogen and oxygen reactions is vital to prevent overheating, as these cells typically operate at around 80ºC. Effective cooling strategies, such as air or liquid cooling with water or glycol-water blends, are essential to maintain optimal operating temperatures.

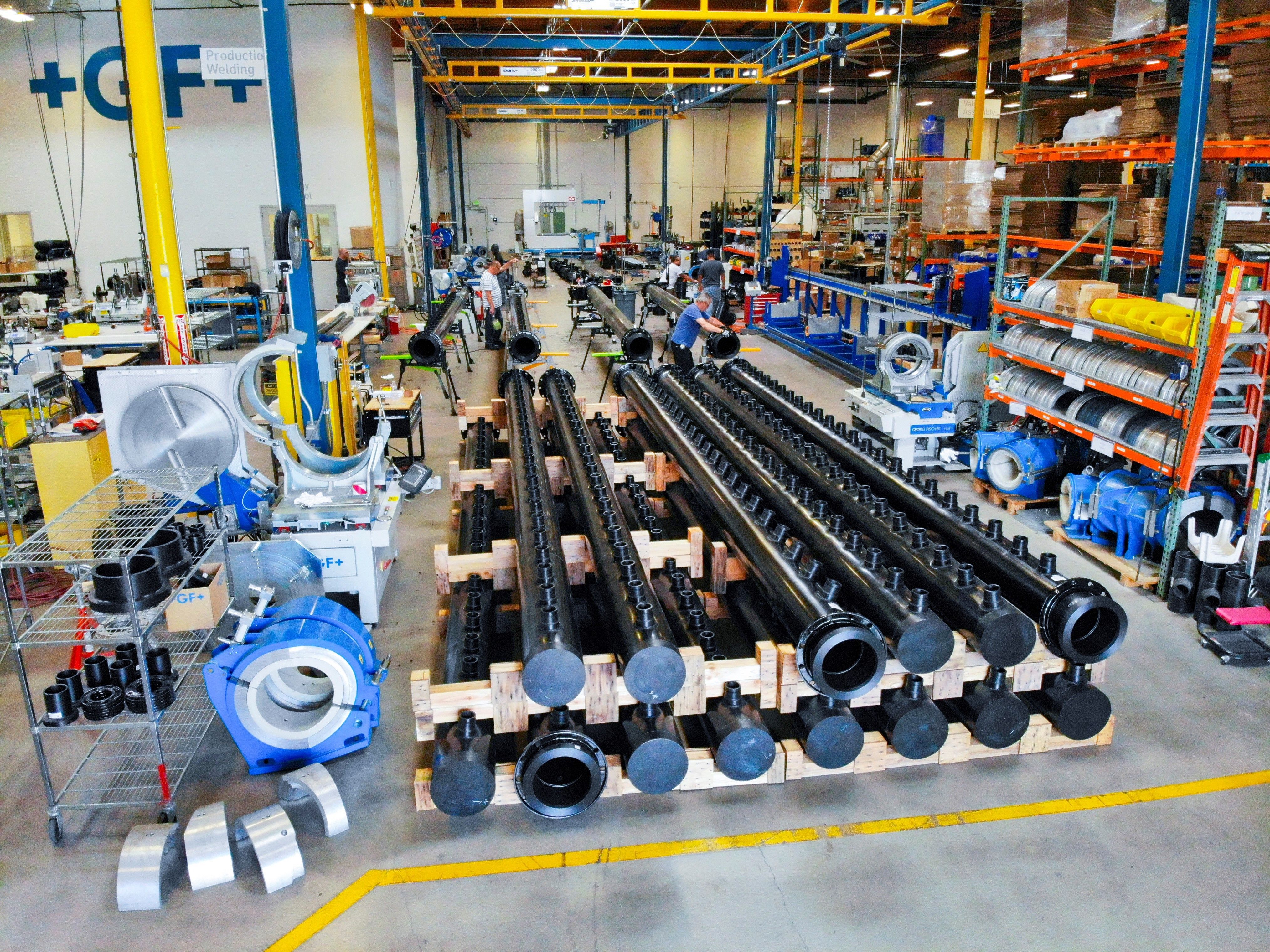

Polymer piping systems like our polypropylene piping solution PROGEF, play a critical role in this process. They offer the following benefits:

- Efficient Heat Dissipation: The polypropylene (PP) welded system handles air and liquid cooling well, effectively removing excess heat to keep the fuel cell at its ideal temperature.

- Durability and Compatibility: PP is suited for fuel cell cooling demands due to its robustness and compatibility with various thermal conditions.

- Flexible Cooling Options: Our polypropylene (PP) welded system can handle different cooling media to effectively regulate and dissipate heat, ensuring the fuel cell's performance remains steady.