Fueling the Future: Seamless Efficiency with Polymer Piping Systems

Proton Exchange Membrane (PEM) fuel cells produce clean energy by converting hydrogen and oxygen into electricity, with water and heat as by-products. They offer high efficiency, rapid start-up, and versatility for various applications. Fuel cells require a steady supply of hydrogen and oxygen to operate efficiently. Precisely controlling and monitoring parameters are crucial for optimal performance and safety, making integration with GF Piping Systems' PROGEF piping systems and automation solutions essential.

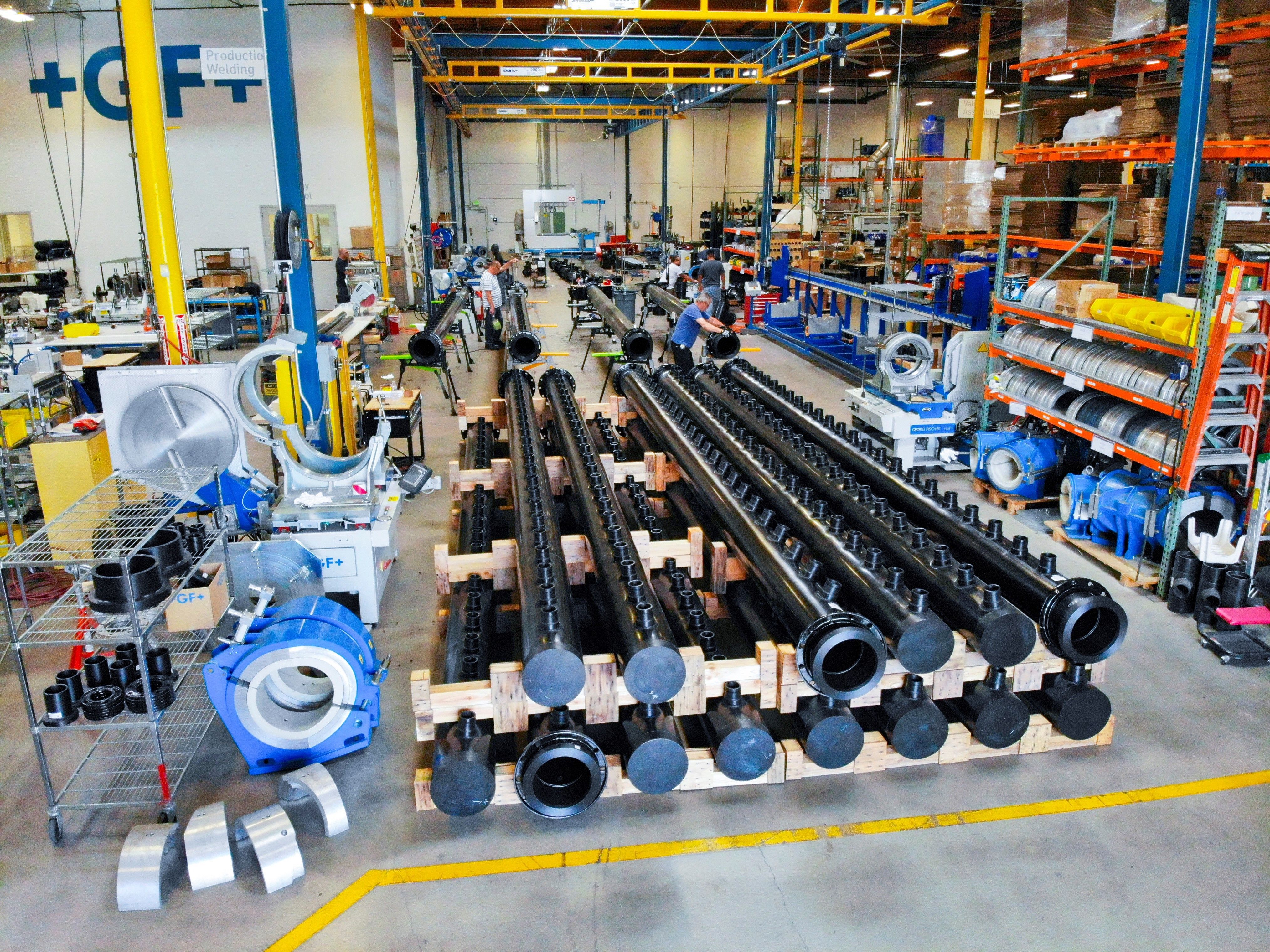

Our polypropylene piping solution PROGEF, known for its high-quality, corrosion-resistant plastic pipes, fittings and valves, ensure reliable transport of gases and liquids. We provide advanced sensors: conductivity sensors maintain water purity, magmeters measure hydrogen and oxygen flow rates, and temperature sensors control operational temperature, ensuring efficiency and longevity.