Corrosion Resistance Excellence

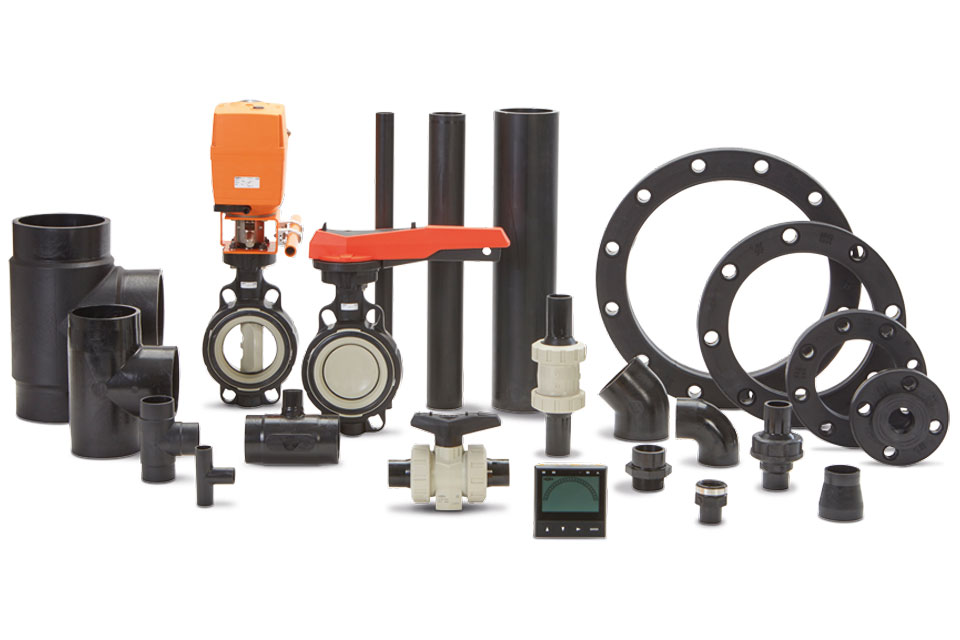

At GF Piping Systems, we support the petrochemical industry by providing corrosion-resistant piping solutions made from materials like PVC, CPVC, PP, PVDF, and ECTFE, which handle aggressive chemicals and reduce maintenance. Our products meet stringent international safety and regulatory standards, ensuring safe and compliant operations. We collaborate with our customers in the petrochemical sector to develop customized solutions for high-pressure applications, extreme temperatures, and challenging conditions. The solutions are designed for optimal flow, minimizing pressure drops and energy consumption, leading to cost savings and improved operational reliability. Our offer includes piping systems, valves and measurement solutions and comprehensive lifecycle support and training to ensure seamless integration and ongoing operational assistance.

?qlt=82&ts=1723596409089&dpr=off)