Selection of proper polymer material and pipe/fitting sizing should be based on the following system design criteria:

1. Facility protocols on system sanitization

- Perhaps the most important question to ask is the method of system sanitization. In many cases this rules out certain polymer materials before any other system parameters are discussed. For instance, if the protocol calls for ozone sanitization, PP may** be ruled out and a PVDF system would be specified – before even investigating pressure, temperature, etc.

- Most commonly used for sanitization/disinfection of polymer systems is peracetic acid solution (Minncare – Mar Cor), others are hydrogen peroxide, chlorine, and potentially hot water.

2. Operating Pressure and Temperature

3. Required Flow in GPM for Risers (Supply and Return) and Floor Loops

4. Required Velocity in fps, typically 3-7 fps.

5 .Required Water Quality in megohm and TOC (Total Organic Carbon) level

6 Contaminant buildup concerns:

- Is Socket Fused System acceptable?

- Is IR (Infra Red) Fused System more desirable?

- Is BCF (Bead and Crevice Free) Fused System required?

- Absolutely NO potential for contaminant buildup allowed

- System requires complete drain ability during sanitization

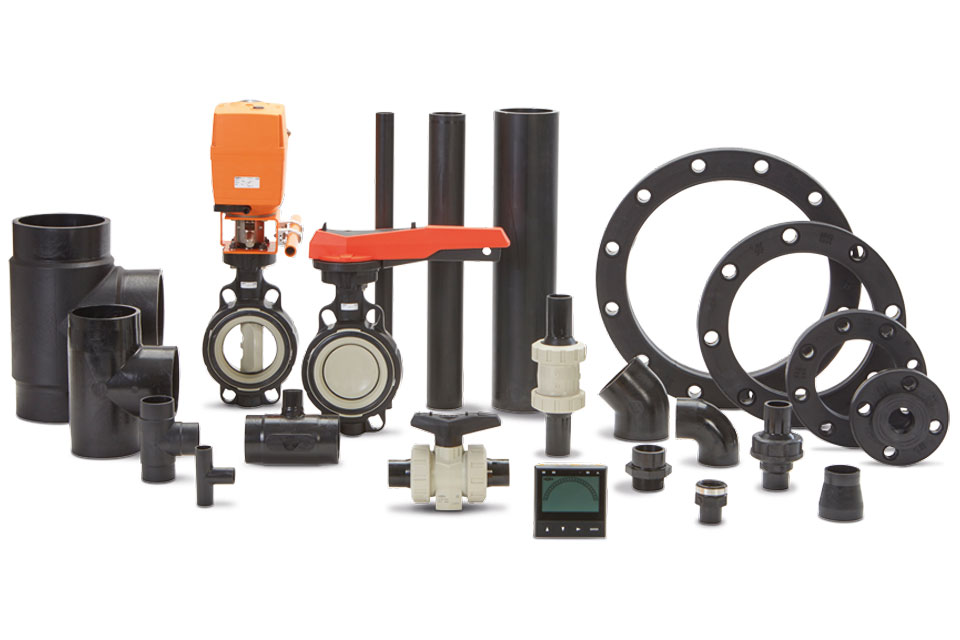

7. Requirement for Valves, PRV’s, Rotameters, etc.

8 .Piping located within plenum?

** dependent upon levels of Ozone

Typical Water Purification Stages

Distribution Piping

The loop must maintain high purity water quality during periods of high usage as well as low usage and deliver the proper amount (flow) of water required to all use points at a constant pressure. Water (flow) must be kept moving to maintain a turbulent flow. No Dead Legs.

Loop Segments

Feed Line:

Piping from final filters to point of use locations. Sized based on flow requirements. Water velocity must be sufficient to allow for turbulence within the line in order to control any possible bacteria buildup.

Point of Use:

Stations where the high purity water is used.

Return Line:

- Delivers the water from points of use back to the storage tank

- Usually about two-thirds to one-half of the circulating water returns to storage.

- Return line may be smaller in diameter than the feed line. Flow rate is generally lower, and the smaller diameter will increase the water’s velocity thus increasing turbulence.