When designing a surface treatment process, consider these five key aspects for effectiveness, efficiency, and safety:

1. Material Compatibility

Select the appropriate surface treatment method based on the substrate material's properties. Ensure chemical compatibility to prevent unwanted reactions or damage. Focus on adhesion properties to ensure the coating bonds properly, providing desired protection and aesthetics.

2. Environmental and Regulatory Compliance

Adhere to local, national, and international environmental regulations regarding emissions, waste disposal, and hazardous substances. Ensure compliance with occupational safety standards to protect workers. Develop a waste management plan, including recycling and disposal methods, to manage process by-products effectively.

3. Process Control and Quality Assurance

Define and control critical process parameters like temperature, pH, current density, and treatment time. Use real-time monitoring and measurement systems to maintain process stability and quality. Establish rigorous quality control procedures, including regular inspections and testing of treated surfaces.

4. Surface Preparation

Properly clean and prepare surfaces to remove contaminants that can affect treatment quality. Additional conditioning steps like etching, blasting, or polishing may be required. Inspect substrates thoroughly before treatment to address any defects or irregularities.

5. Cost and Efficiency Considerations

Evaluate material and chemical costs, seeking optimization. Reduce energy consumption through efficient equipment and process parameter optimization. Design with automation and scalability in mind to improve efficiency, reduce labor costs, and meet production demands. Plan regular maintenance to minimize downtime.

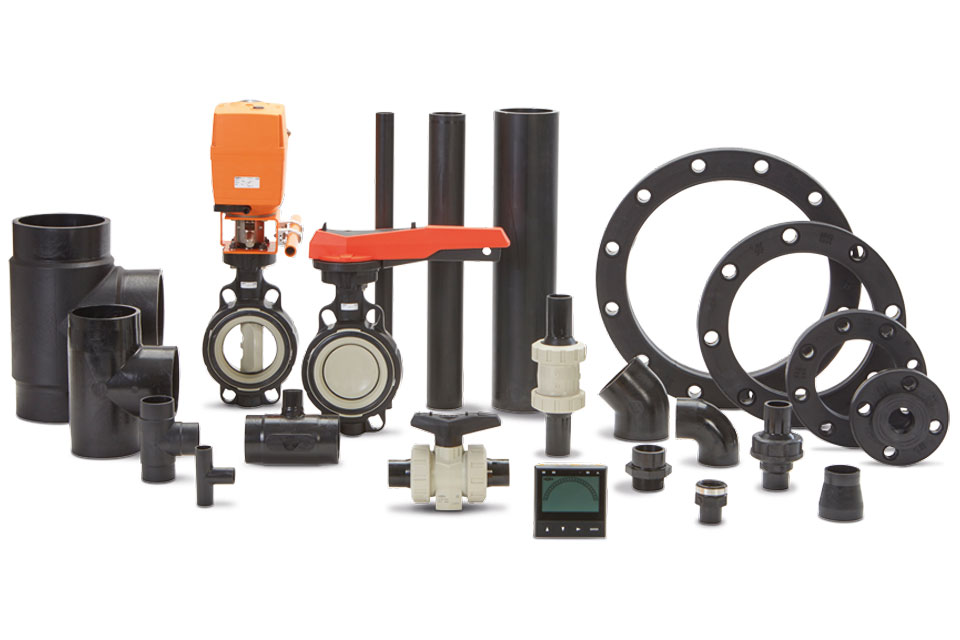

At GF Piping Systems, we offer engineering support and the best in class pipings, valves and measurement instrumentation portfolio to help you make the right design choice.