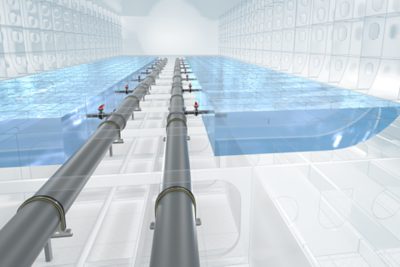

The demand for thermoplastic piping systems has grown considerably over the last few years. The lightweight, corrosion-free, and long-lasting alternative to traditional steel and metal piping systems is the ideal solution to increase the efficiency of cruise ships, merchant fleets, offshore platforms, and floating wind farms. Thanks to the newly developed Fire Retardant Pipe Jacket System HEAT-FIT, thermoplastic piping systems can be used for essential applications (L3) onboard.

Ultimate protection

HEAT-FIT is protecting thermoplastic piping systems from fire up to 1,000°C for 30 minutes under pressure (3 bar). Based on intumescent technology, the pipe jackets are designed to cope with the harshest marine environmental conditions.

Ultimate compatibility

Compatible with the PE100 piping system ecoFIT and is designed for fast and straightforward new build and retrofit installations. No specilized skills required for jointing of inner pipe with electrofusion or butt fusion and manual installation of fire retardant jackets.

Ultimate safety

The HEAT-FIT Jacket material is water-based and is environmentally safe, even in the case of fire. Does not contain halogens, asbestos, or any other hazardous material and complies with the Green Ship Passport regulations (Hong Kong Convention).

Ultimate approval

HEAT-FIT meets the requirements of the International Maritime Organization (IMO) and is approved with ecoFIT/ELGEF for essential and non-essential applications. The Jacket System complies with IMO Resolutions A753 for fire endurance L3, MSC 399, and FTP code parts 5 and 2 related to surface flammability, smoke, and toxicity. Also, it is approved by ABS, BV, DNV, LR, and RINA.

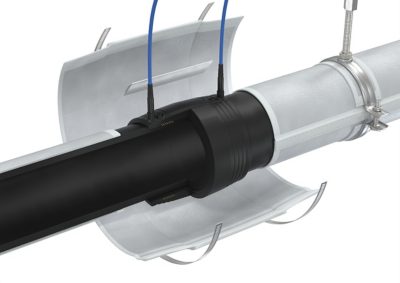

The unique Pipe Jacket System HEAT-FIT copes with the strict fire resistance regulations of the International Maritime Organization (IMO) and makes thermoplastic piping systems resistant to temperatures around 1,000°C for at least 30 minutes under pressure. The Pipe Jackets are made of durable and flexible materials and can sustain highly demanding marine industry conditions.

Please accept all cookies to view the youtube video content.

Ultimate fire protection

Impact of plastic piping systems on industry challenges

Watch this video and learn why shipbuilders, shipowners, and operators should consider lightweight plastic piping systems for essential and non-essential applications onboard cruise ships, merchant vessels, and offshore work.

Please accept all cookies to view the youtube video content.

How the fire retardant pipe jacket system was developed

The HEAT-FIT Jacket solution provides ultimate fire protection for plastic piping systems onboard essential applications (L3). The road to the final product has taken more than six years of research, development, and testing.

Please accept all cookies to view the youtube video content.

Working principle of HEAT-FIT Jacket System

The HEAT-FIT material consists of three components. Watch this video to learn more about the different materials and technologies used to provide ultimate fire protection for your plastic piping systems in essential applications onboard.

Please accept all cookies to view the youtube video content.

L3 application possibilities for lightweight plastic piping systems

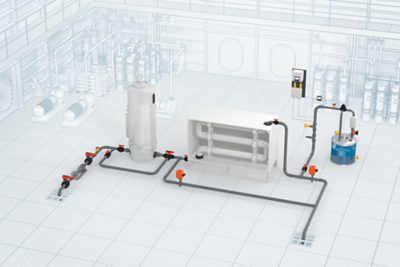

Corrosion-free plastic piping systems can finally be applied in essential applications (L3) like ballast water, ballast water treatment, fresh- and seawater cooling, or exhaust gas scrubbers. Watch the video to learn more about HEAT-FITs application possibilities and approvals.

Please accept all cookies to view the youtube video content.

HEAT-FIT Jacket Material

The HEAT-FIT Jacket system is highly insulating and strong, protecting the medium carrying inner pipe from fire by expanding when in contact with fire.

- Intumescent Coating protects the medium carrying PE piping system ecoFIT from fire by expanding and when in contact with fire.

- Thermoplastic polyurethane (TPU) protects the high-temperature fiberglass fabric and the intumescent coating from the harsh environment at sea.

- High-temperature fiberglass is the carrier material of the highly resistant marine-proof system.

- Speak to one of our experts to learn more about the HEAT-FIT material

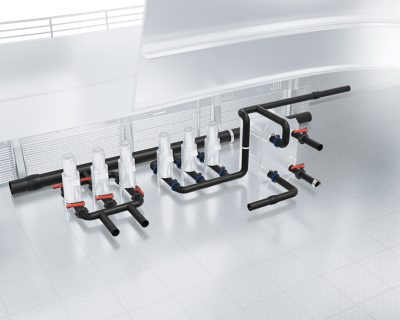

Jointing Technologies

Combined with GF’s ecoFIT piping solution, the lightweight system is installed within minutes for years of operation. While the inner PE piping system is jointed with butt fusion or electrofusion, the HEAT-FIT jacket system is installed manually. For the installation of the total system, no specialized skills nor hot work are necessary. The long-established jointing technologies allow the highest reproducibility, reliable joints, and low thermal and mechanical stress during the installation process. In addition, the welds are trackable and recordable.

Applications

GF Industry and Infrastructure Flow Solutions has been the global marine industry partner for over 30 years and supplies non-corrosive and lightweight thermoplastic piping systems. Thanks to the innovative fire retardant pipe jacket system HEAT-FIT, the range of applications of thermoplastic piping systems has been extended from non-essential to essential applications.

Application possibilities are in machinery spaces, pump rooms, cargo pump-rooms, RO/RO cargo holds accommodation services, and control spaces as well as open decks under the categories A, B, C, D, J, and K of the fire endurance matrix according to IMO A. 753 (18) regulations.