High-quality plastic pipes for demanding industries: Deka has been setting standards with pipe systems made of high-performance materials for the chemical and petrochemical industries since 1960.

Whether corrosion-resistant or thermally stable, Deka pipe systems are more than just plastic. Since 1960, the specialists have been reinventing the plastic pipe time and again. From the preparation of materials according to our own formulas, via production and finishing, to Europe's largest high-rack warehouse for plastic pipe systems. Whether PP, PE, PVC or high-performance thermoplastic, Deka, which joined Georg Fischer in 1998, sets the standard.

Water Treatment

For decades, we have been supporting our customers with advice and assistance to realise their ideas and guarantee functioning assemblies under specific application parameters.

Our wealth of experience includes the extrusion of casing pipes from suitable materials and our own formulations in the PVC-U and PVC-C range, their refinement and further processing (mechanical processing, bonding, welding, joining, production of turned parts and connection heads), as well as the production of customised connection solutions for individual modules made of PE.

These parts find their way into various applications for the production of clean water for process technologies, supply, laboratory and drinking water applications by means of ultrafiltration, reverse osmosis and other common processes.

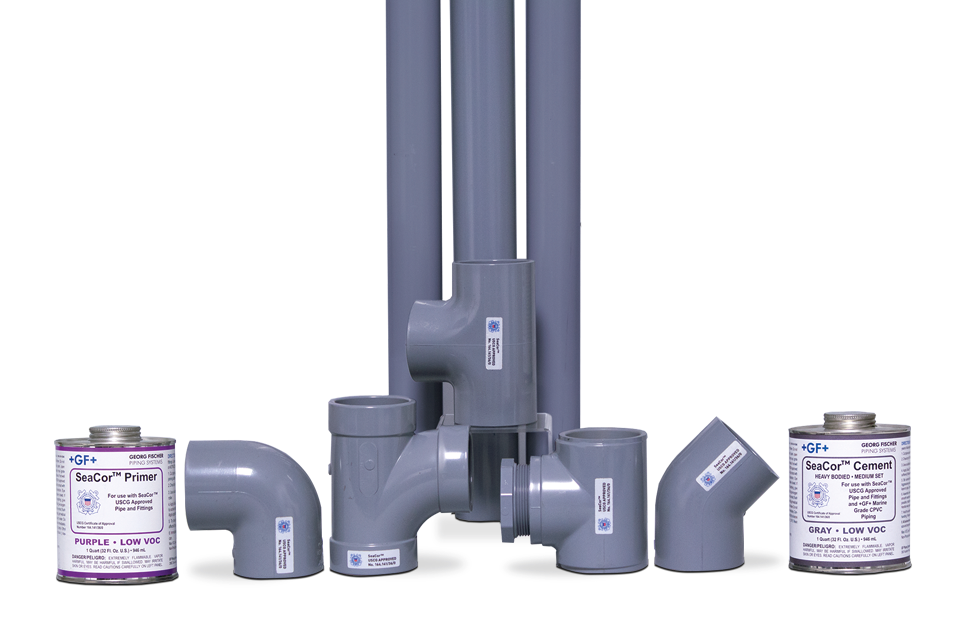

Standard Plastic Pipes

Standard Plastic Pipes

Medical technology

We supply our customers in the medical technology sector with high-quality housing tubes and peripheral parts made from special PP and PVC formulations. Our daily aspiration is the improvement of existing products and the the expansion of our activities.

Chemical Process Industry (CPI)

Georg Fischer DEKA GmbH has over 40 years of experience and competence in the development and production of industrial pipe systems. One result of this know-how potential is the production of customised system solutions for customer-specific applications. Long service life due to processing adapted to the material, special formulation and low-stress production in accordance with established standards or own operating equipment regulations. The pipes achieve excellent chemical resistance through special manufacturing processes and the coordinated formulation in the area of PVC in liner production.

Microelectronics

The production of processor units is gaining worldwide importance every day. The caligraphy units required for this are fitted with assemblies and finished modules manufactured by us. These are adhesive part combinations of pipe - moulded part and malleable cast iron fittings from the +GF+ portfolio.

Customized Extrusion

Since the earliest days, we have been involved in the extrusion of plastics that meet our customers' special requirements for particular shapes, colours, dimensions and special materials. Over the decades, we have contributed to the development of special materials and high-tech materials for our partners, as well as building up our own formulation portfolio. Since then, we have been constantly interested in breaking new ground and realising new technologies (nano, coating, joining technology).