Mission-Critical Water Solutions for Efficient Operations

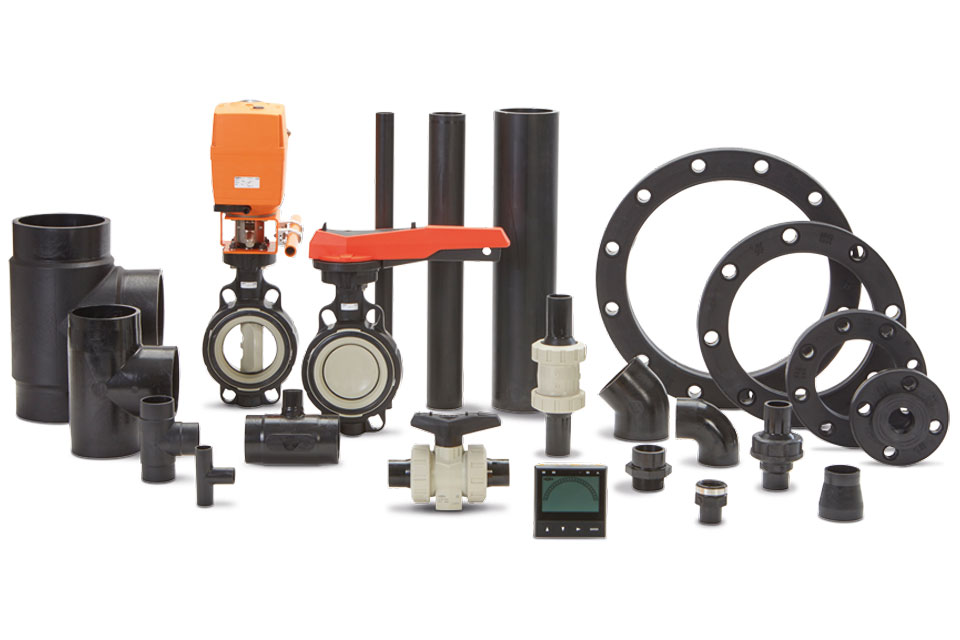

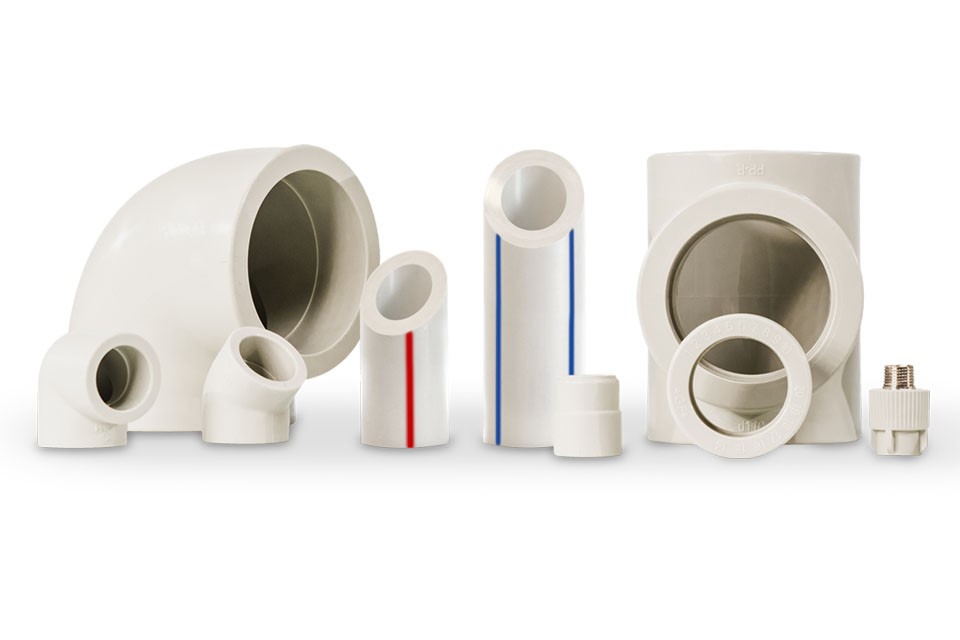

The reliability of container ships, bulk carriers, trawlers, and LNG carriers is paramount. We are committed to enabling the safe and sustainable handling of water, gas, and chemicals at sea that are compliant with the latest regulations. Selecting lightweight, long-lasting, corrosion- and maintenance-free piping systems helps improve the environmental impact by expanding the system's service life and reducing the overall ship weight and fuel consumption over the whole service life.