Safe Chemical Gandling

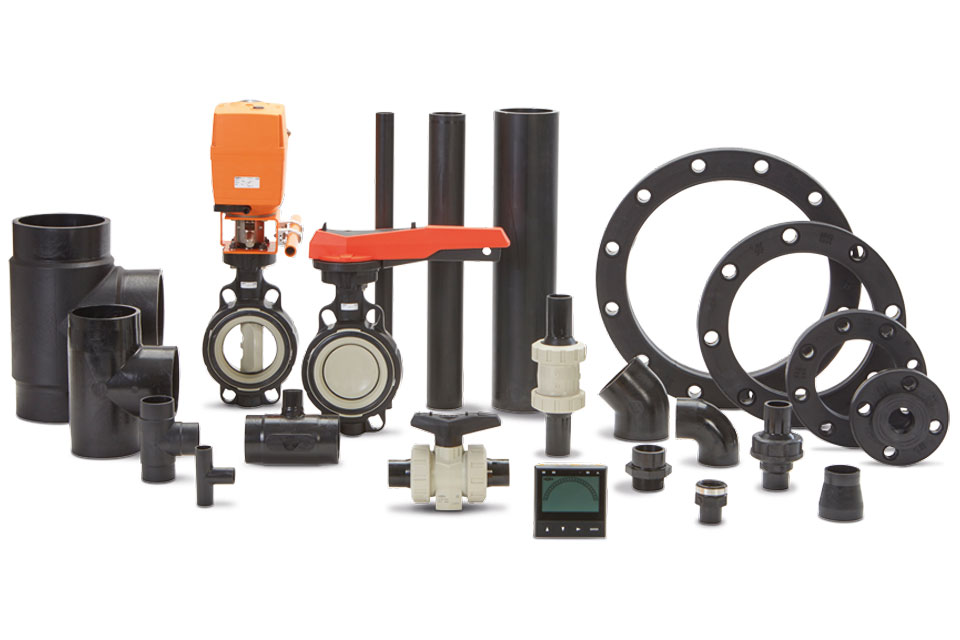

Handling chemicals in the distribution industry involves significant challenges, including ensuring safety against hazardous materials, complying with complex regulations (e.g., OSHA, REACH), and managing specialized logistics. At GF Piping Systems, we enhance chemical distribution by ensuring safety and regulatory compliance. Our certified, modular systems facilitate efficient logistics, reduce transportation costs, and simplify inventory management. Advanced leak detection and smart, automated controls improve operational transparency and efficiency, supporting environmental responsibility and effective waste management. Our comprehensive training and ongoing technical support ensure safe, optimal system use. Expert consultation and responsive service address customer needs quickly, mitigating industry challenges and ensuring reliable, efficient chemical handling and distribution.

?qlt=82&ts=1723594603374&dpr=off)