Depending on the application and the used piping material, GF Piping Systems offers a variety of jointing technologies tailored for marine environments, including socket fusion, butt fusion, electrofusion, and solvent cementing.

These methods are chosen for their ability to provide secure, reliable connections:

- Socket fusion: Known for creating homogeneous connections, socket fusion is ideal for robust installations both onshore and offshore. Its precise temperature control minimizes quality loss during welding processes.

- Butt fusion: This method stands out for its simplicity and automated functions, ensuring quick setup and high precision through precise weld parameter control. It is particularly effective for large-diameter pipes, meeting stringent marine requirements.

- Electrofusion: Utilizing lightweight equipment, electrofusion offers a semi-automatic process that enhances operational ease. It enables traceability through weld data storage and supports configurable workflows, ensuring robust quality control throughout the jointing process.

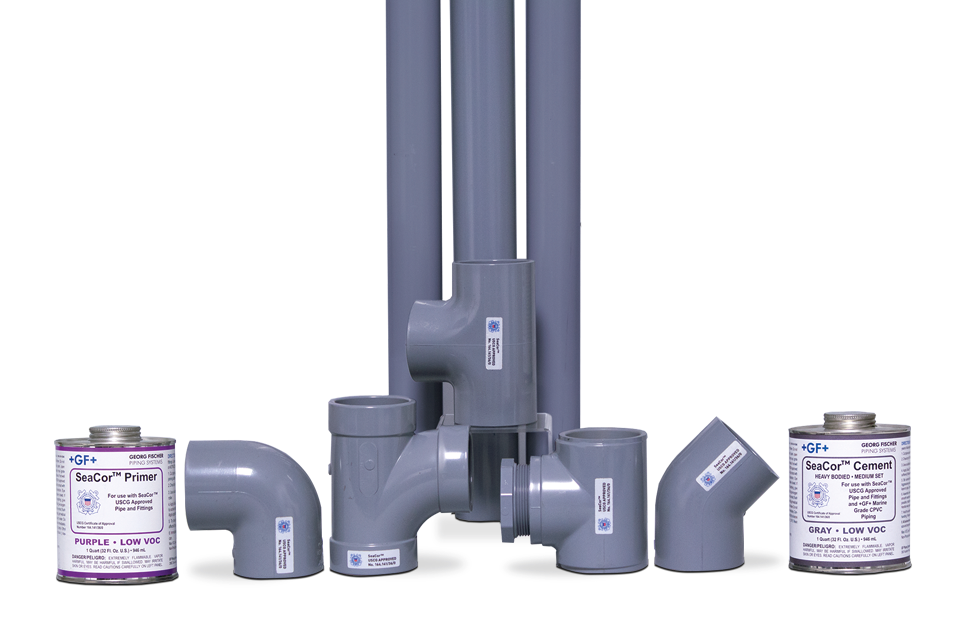

- Cementing: Applied for specific materials like SeaCor (PVC-C), solvent cementing provides a simple, economical method to create secure, leak-proof joints with minimal expertise. GF's piping systems and cements are marine-approved and designed for durability in harsh marine conditions.

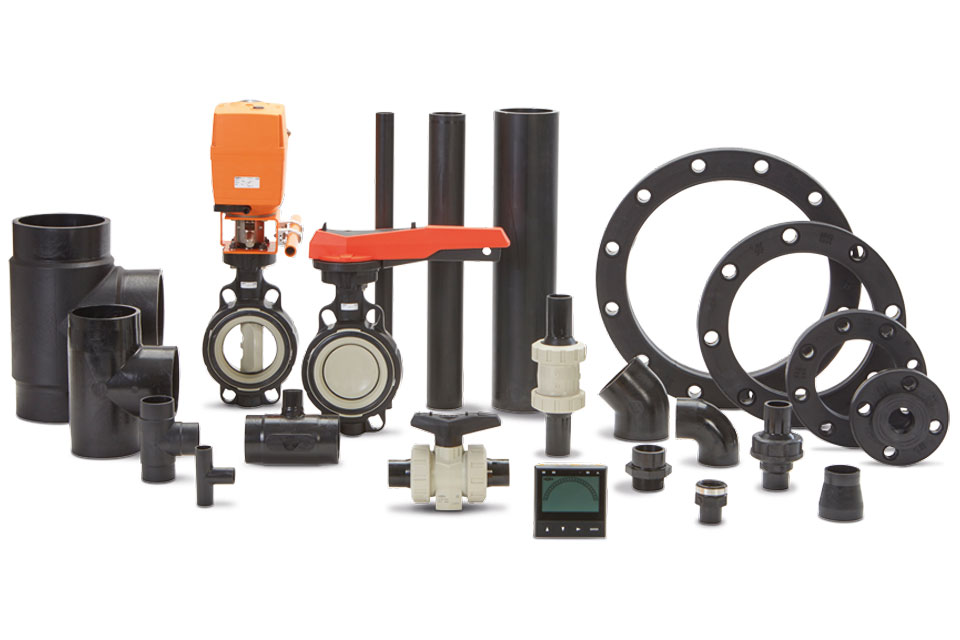

Additionally, GF Piping Systems provides solutions such as Flanges and Threaded Joints to connect plastic pipes to existing installations onboard ships. Prefabrication options further streamline installation and maintenance processes, reducing labor hours and improving project efficiency for shipyards.

Each of these technologies serves specific needs within the industry, combining reliability with technological advancements to meet diverse project requirements effectively.