Improving Well Established Processes

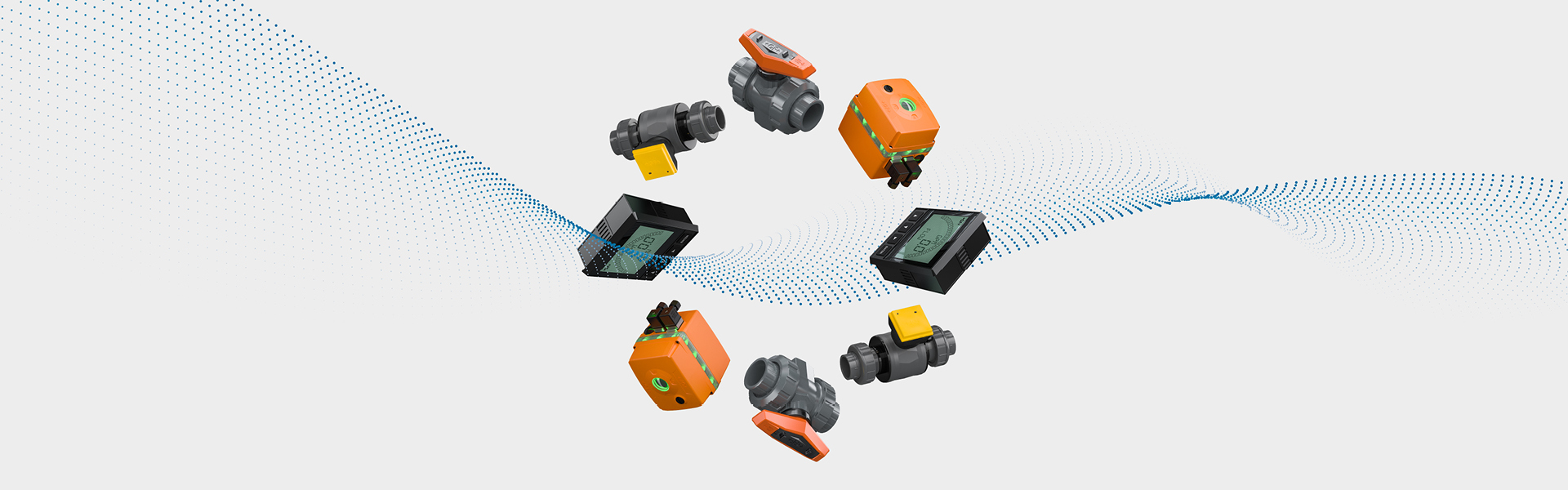

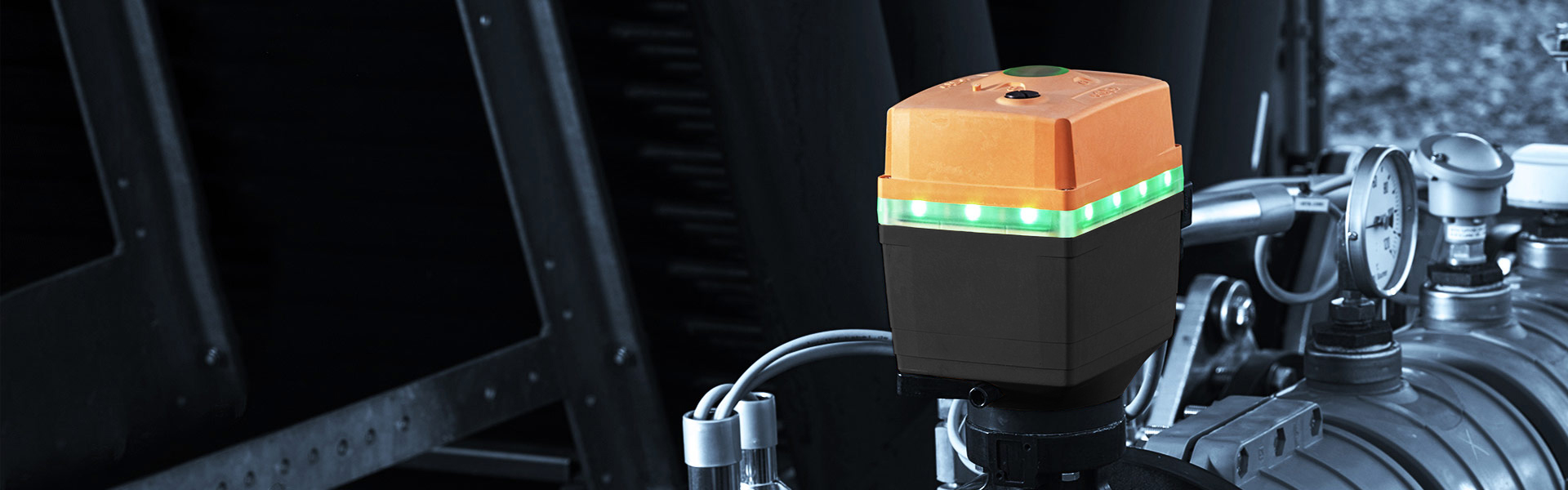

Media filtration is a key process in industrial filtration systems, commonly using sand, anthracite, or stones to remove solid particles from water. These filters feature a multi-layered bed, where materials increase in density from top to bottom, ensuring efficient particle capture. In sand filters, pressurized water flows top-down through these layers, trapping particles as small as 10-15 μm. Typically used as pre-treatment in water production plants, these systems require multiple flow processes, including operation, backwash, and rinsing. This setup involves numerous valves, bypass actuators, and precise instrumentation to ensure optimal performance.

Thermoplastic piping systems are ideal for media filtration due to their corrosion resistance, lightweight construction, and ease of installation. They handle the demanding conditions of multiple flow processes while providing long-term durability and minimal maintenance.