Introduction

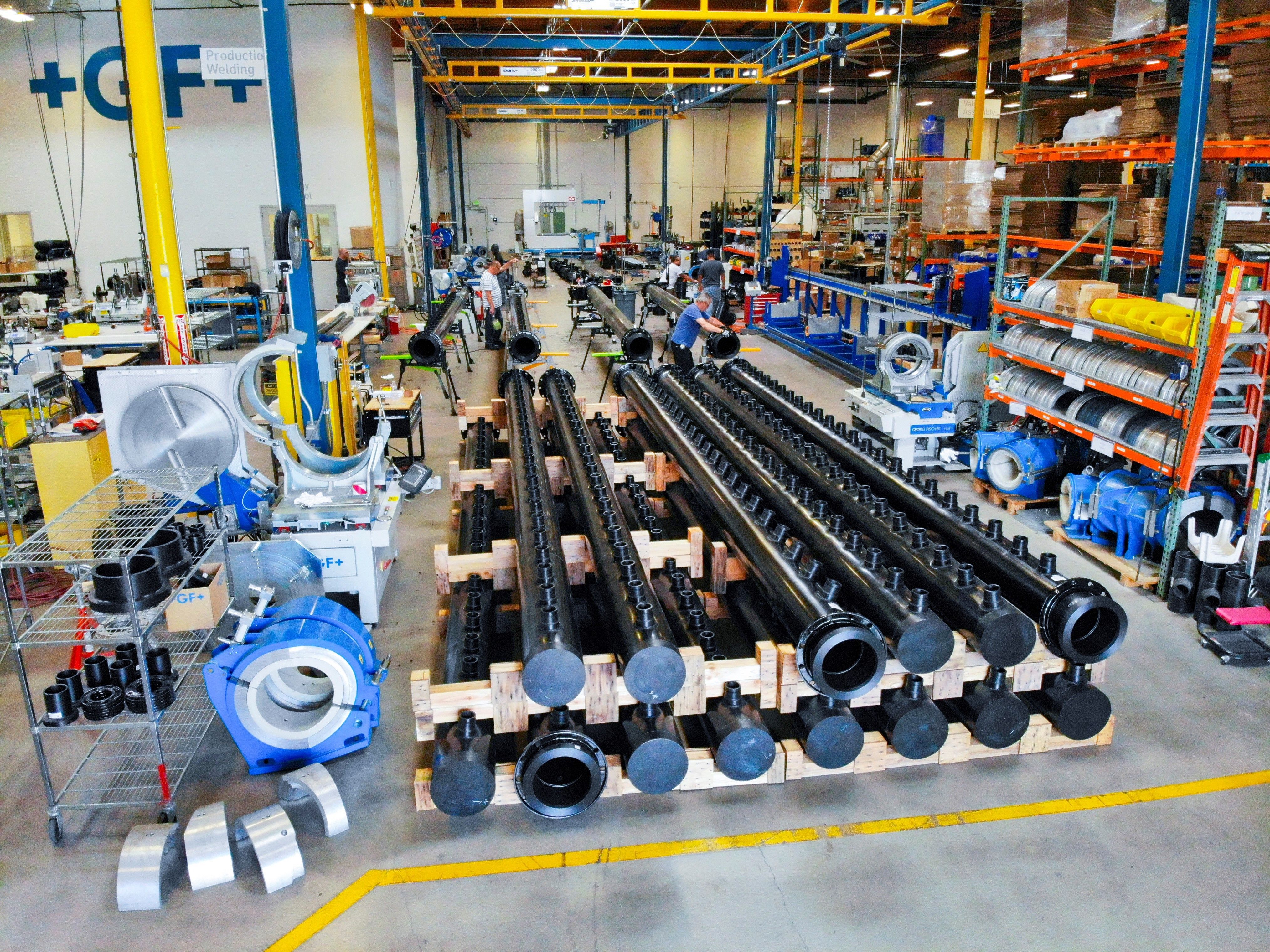

GF Piping Systems provides significant benefits for energy storage and pumped storage hydropower applications. Our reliable, corrosion-resistant solutions ensure safe electrolyte handling, guaranteeing low pump and minimized shunt loss, while advanced plastic materials provide long-term durability, low maintenance, and optimal performance in demanding environments. Our piping solutions are crucial for thermal management, ensuring safe operating temperatures and maintaining the performance and longevity of large-scale energy storage units. By supporting these advanced technologies, we support the integration of renewable energy sources into the grid, contributing to a more sustainable energy future.

?qlt=82&ts=1727856157201&dpr=off)

?qlt=82&ts=1733210226898&dpr=off)