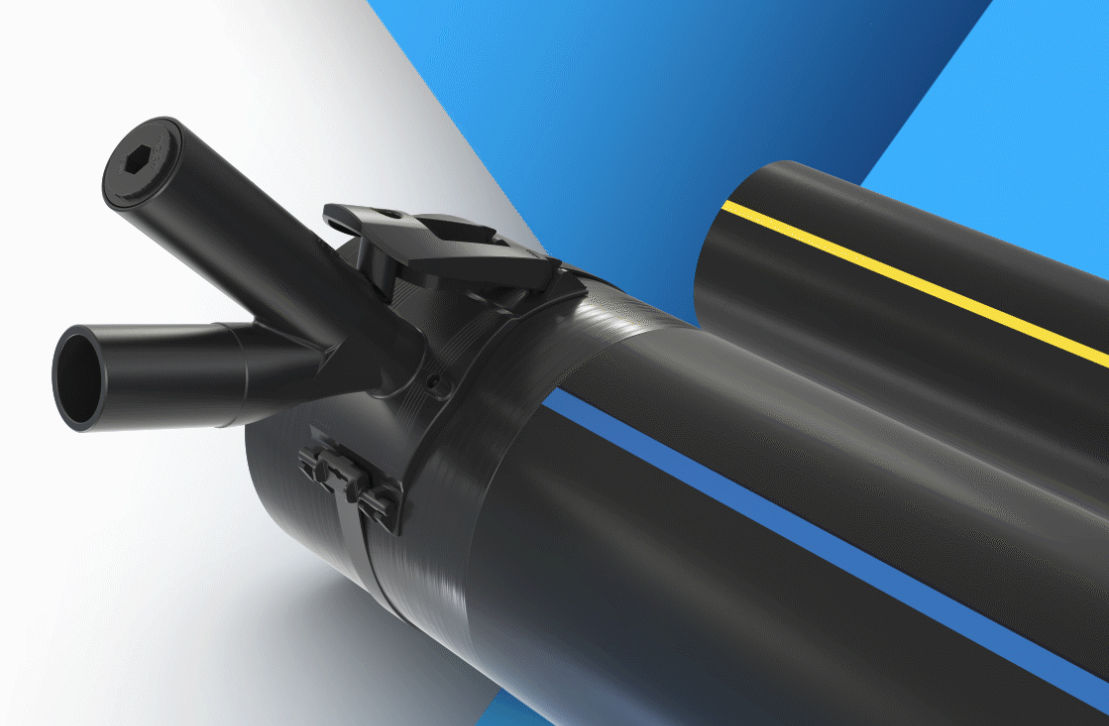

Electrofusion is a straightforward method for joining polyethylene pipes in house connection applications (water and gas). For heating element fusion jointing, plastic pipes are connected using electrofusion fittings until they are permanently joined together. Our electrofusion fittings (couplers, fittings, and saddles) have integrated resistance wires to which electric current is applied during the fusion process. This heats the inside of the fittings and the outside of the pipe to the fusion current temperature, melting them. The measurements of the outer pipe diameter and the fitting correlate to achieve fusion pressure during jointing, resulting in a homogeneous joint. The welding pressure required for the polymer melt is due to the volume increase of the melt and the fitting design. The fusion data transfer of the fittings is carried out using bar codes logged with the fusion device. After cooling, a permanent, homogeneous joint is formed.

Advantages of Electrofusion:

- Pull-out resistant, so no buttress is required for underground lines

- Jointing of pipes of the same material types (PE 80, PE 100, PE 100-RC) and combinations thereof

- Different SDR classes can be welded together

- No fusion bead on the inside of the pipe

- Low space requirement due to lightweight and compact fusion devices

- Fully automatic fusion process with high process reliability

- Gap-free traceability through fusion protocols and identification of welded components

- Low investment needed because welding of all dimensions occurs with one fusion device

Electrofusion machines, compact and portable, are crafted from robust materials, allowing use in harsh conditions with minimal space. They offer excellent data storage options and are configurable with little advance training required.

In addition to electrofusion, we recommend using compression connections, with our iJOINT system. This jointing technology is specifically designed for house connections and service lines in water applications, offering high pressure resistance and excellent pull-out strength. Its innovative design facilitates fast, forgiving, and effortless installation, even in challenging trench and weather conditions. Whether for new installations or renovation work on existing lines, this versatile system delivers reliable results.