We empower sustainable transition and digital transformation for the maritime industry. Our first-in-class plastic piping systems ensure the sustainable treatment and transportation of fluids onboard cruise ships, merchant vessels, offshore platforms, and wind farms at sea.

We are committed to enabling the safe and sustainable transport of water, gas, and chemicals at sea that are compliant with the latest regulations. Our teams develop application-oriented thermoplastic piping solutions for essential- and non-essential applications that enable fast and easy installation, profitable operations, and environmental benefits. We support our customers in implementing sustainable, future-oriented, and well-designed piping concepts with state-of-the-art planning techniques to optimize the economic efficiency of processes.

Future reliability

Future sustainability

Lightweight thermoplastic piping systems have a lower GHG footprint than metal alternatives. Our piping systems comply with the Green Ship Passport and are made of recyclable materials and we provide environmental product declarations.

Future automation

Our experts provide a deep application knowledge of the entire process within the water treatment onboard. We offer a true partnership with a unified vision toward active water conservation. Our solutions for automated flow processes ease the way toward autonomous vessels.

Future integration partner

With 36 production facilities and a global presence of our sales representatives and consultants in 100 countries worldwide, we help you realize your new build or retrofit project from planning to commissioning.

Full solution provider

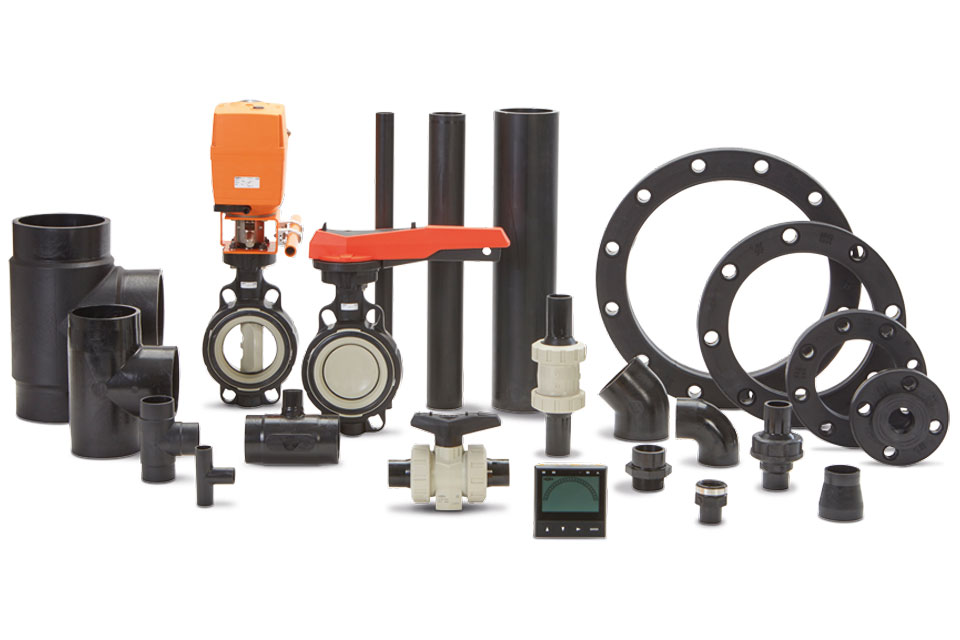

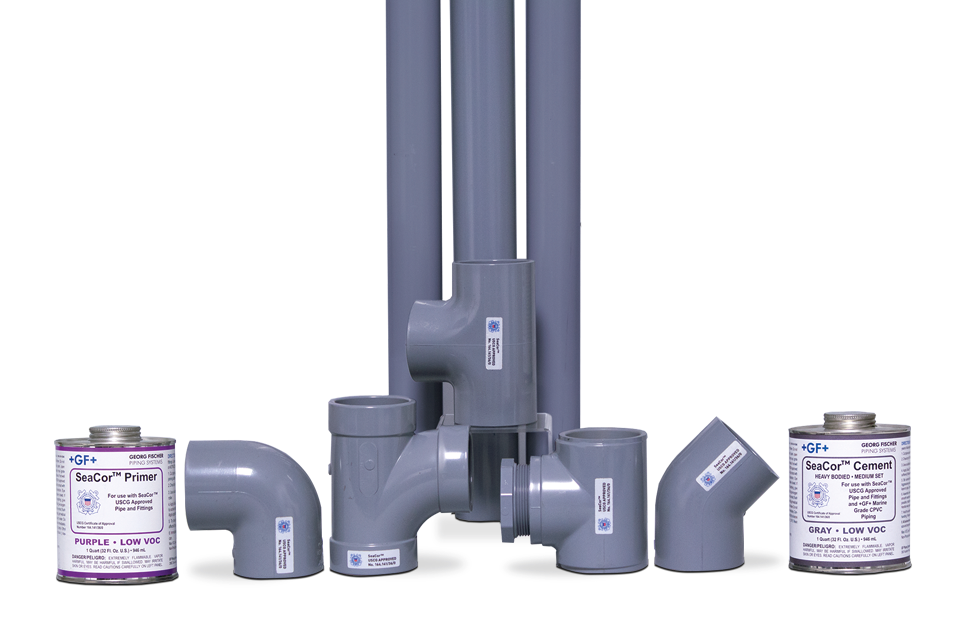

GF Piping Systems is a provider of complete piping solutions with the customer in focus for fast and customized project delivery. Customers around the globe benefit from the broad material selection, automation solutions, and services like Engineering, Digital Libraries (CAD Libraries), or Custom Product Design and Prefabrication. Learn how our products and services have helped other customers in the maritime industry with a fast and efficient pipe renovation project on a 92.000 GT cruise ship.

Applications

Our piping systems and automated flow solutions are made of lightweight, corrosion-free thermoplastics materials like for example PVC-U/C, Polyethylene (PE), Polypropylene (PP), or Polybutene (PB), cover applications for the transportation of water, seawater, coolants, and sewage onboard cruise ships, ferries, mega-yachts, container ships, bulk and LNG carriers, OSVs, wind farms, and offshore energy platforms.

Route to decarbonization

The most significant long-term challenge the maritime industry is facing is sustainability. International shipping causes around one billion tons of CO₂ each year or 2,5% of global greenhouse gas emissions. If the industry were a country, this would make it the sixth-largest emitter in the world. As a result, more and more international standards require shipbuilders, owners, and dockyards to find solutions that reduce greenhouse gas (GHG) emissions as quickly as possible. As a company that is active worldwide, our mission is to show our commitment by supporting our customers' success with innovative, energy-saving solutions that make the collective global footprint more sustainable.

Please accept all cookies to view the youtube video content.