Extract What Matters

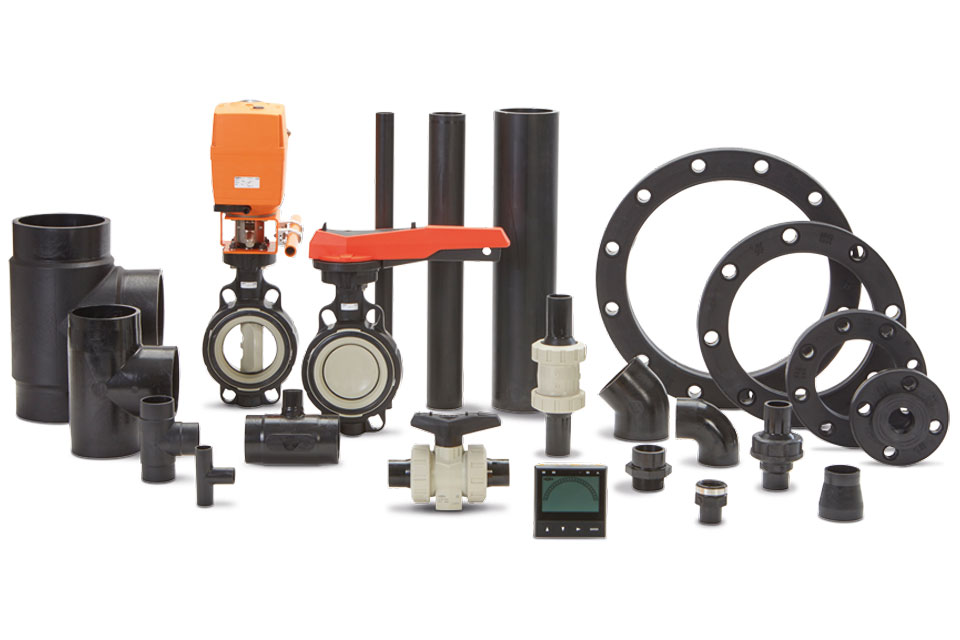

Piping systems play a crucial role in mining extraction, ensuring the efficient transport of water, slurries and other fluids. Engineers must balance reliability, availability, capital costs, efficiency, and environmental responsibilities when designing complex pipelines. GF Piping Systems' solutions are used for decades in mining as they are long lasting, maintenance free, non-corrosive and flexible. High-density polyethylene (HDPE) pipes and fittings are commonly used to distribute water to, from and around mine sites. Increasingly, legislation demands water movement in pipelines to be monitored or metered. Our flow measurement instruments are ideal for water monitoring.