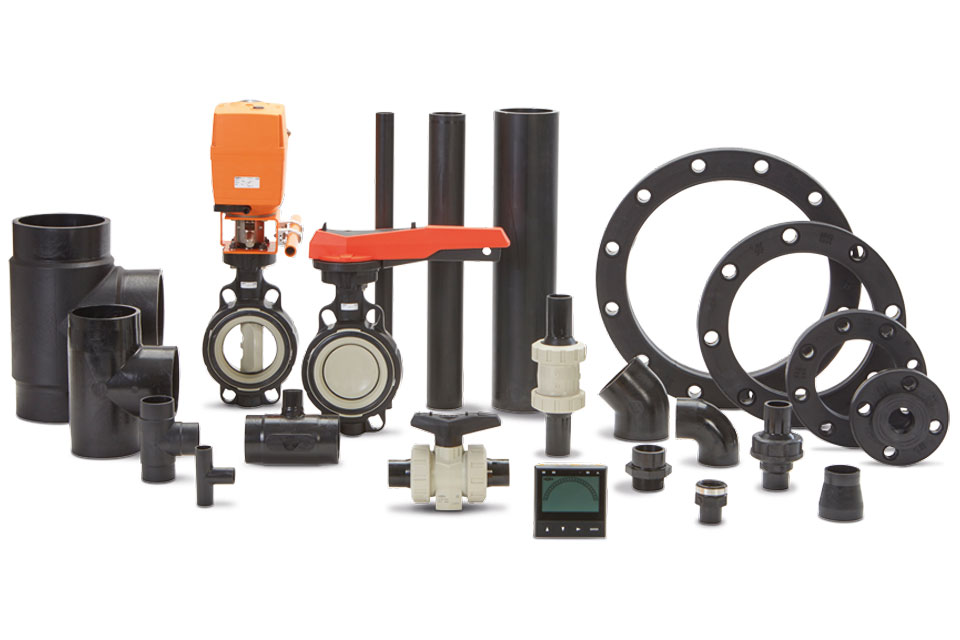

GF Piping Systems leads the way in long-lasting corrosion and maintenance-free solutions for large dimensions up to d2000. Our comprehensive PE systems offer fast, safe and reliable zero leakage connections with expected 100 years of lifetime. Customizing teams forge the best solution that fits you, with off-site prefabrication, developing custom-made parts and individual consulting.

What are the top four issues that operators and engineers face when working with large dimension building projects? Find out how GF Piping Systems experts can solve your pipeline challenges in water and gas supply.

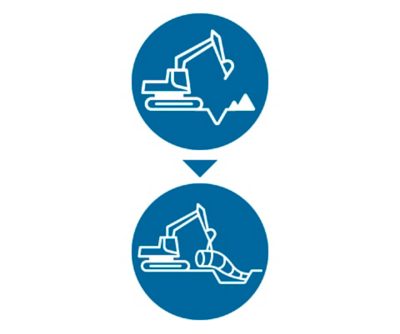

Are you struggling with the effects of rigid pipe installation?

Big, open-trench methods are needed when rigid ductile iron pipes or steel pipes are used, while also demanding more safety and certificates for welds.

Trenchless laying

The flexibility of a PE system allows for trenchless laying. This reduces construction times, meaning less excavation work and costs on the surface and avoids disturbance to the population and infrastructure.

At a loss on how to reduce non-revenue water?

33% of the world's drinking water is lost due to leakage in the aging infrastructure.

Corrosion-free and reliable connections

PE systems have an expected lifespan of at least 100 years. They do not corrode and therefore are maintenance- and leak-free. PE welds are fused to make a single piece and are weatherproof to remain impact-resistant under all climatic conditions.

Not sure how safe your installation is?

Bad installations on gas pipelines cost on average € 1 Million – which often fail due to improper installation.

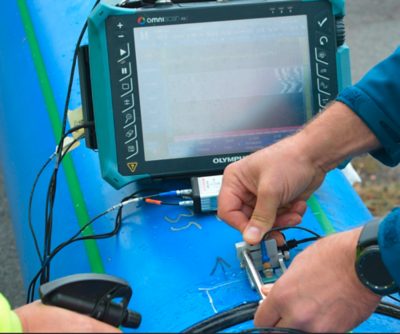

Ultrasonic NDT

For complete peace of mind, digitized solutions like Non-Destructive Testing (NDT) provide ultrasound scans to look for any potential defects and tightness of welds and pass tests, assuring safety before operations begin.

Do you need training and on-site support?

Do you lack experienced installers for installation?

On-site training and support is critical to the proper installation because this influences the total service life of your system.

Training – Specialized Education

Instructional courses and on-site support in the local language can help you to teach your customers or installers essential knowledge for the welding of pipes and piping components

Getting everything from one source means comprehensive solutions that are perfectly compatible and customizable without any limits in designing your piping networks. A combination of fittings and tools with state of the art fusion and jointing technology results in reliable and cost-efficient installations.

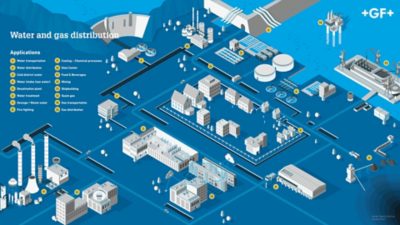

Discover all the application areas where GF Piping Systems can support you:

Large-dimension building projects demand materials that are up to the task. Developers and operators continuously face corrosion issues that lead to expensive damages and water leakages, when working with metal piping systems. Here we provide you with some examples of our reference cases on how to build a big, tight and reliable pipeline with PE for an expected lifetime of 100 years. Contact us for your next big project.

Please accept all cookies to view the youtube video content.

Please accept all cookies to view the youtube video content.

Please accept all cookies to view the youtube video content.