Boost Efficiency and Sustainability with GF Piping Systems' Innovative, Non-Corrosive Solutions

The surface treatment industry faces significant challenges, including environmental regulations, high operational costs, and the need for advanced technologies. Companies are striving to reduce hazardous waste, improve energy efficiency, and enhance the durability of treated surfaces. Innovations in eco-friendly coatings, automation, and precision techniques are key to addressing these issues.

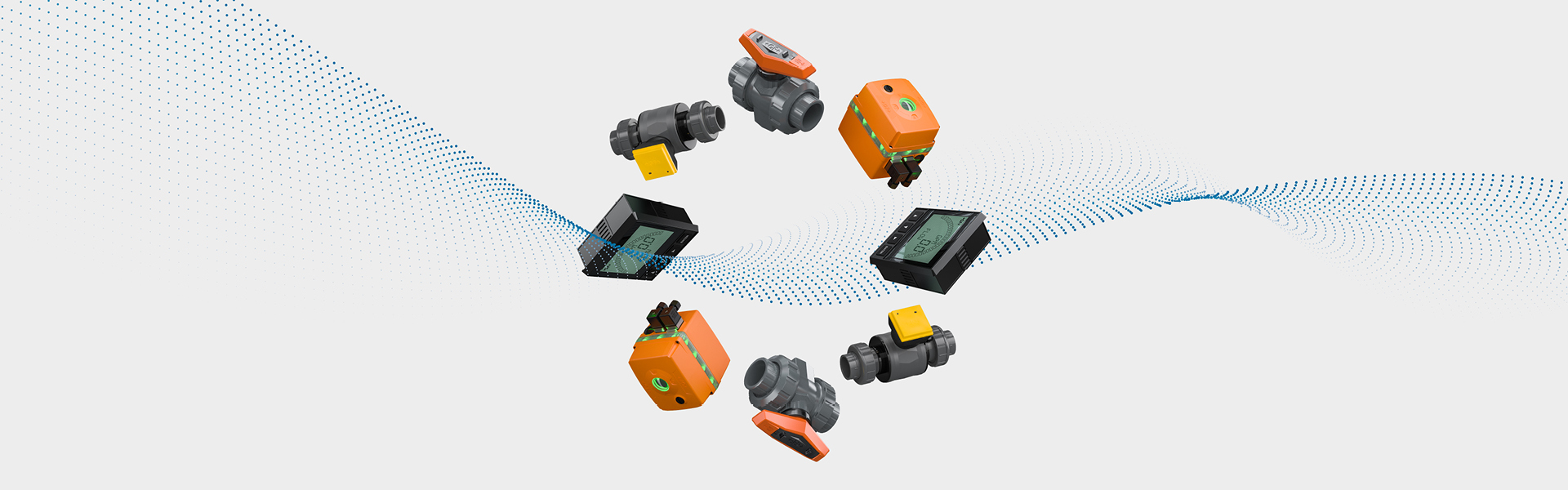

GF Piping Systems can significantly enhance efficiency and automation by integrating advanced technologies. Our non-corrosive plastic components ensure long-lasting durability and minimal maintenance, which is crucial for maintaining high efficiency. Additionally, GF Piping Systems provides precise measurement tools that allow for accurate monitoring and control of fluid systems. This combination of innovation, automation, and reliable materials helps achieve optimal performance.