Visit us at Stand DC142

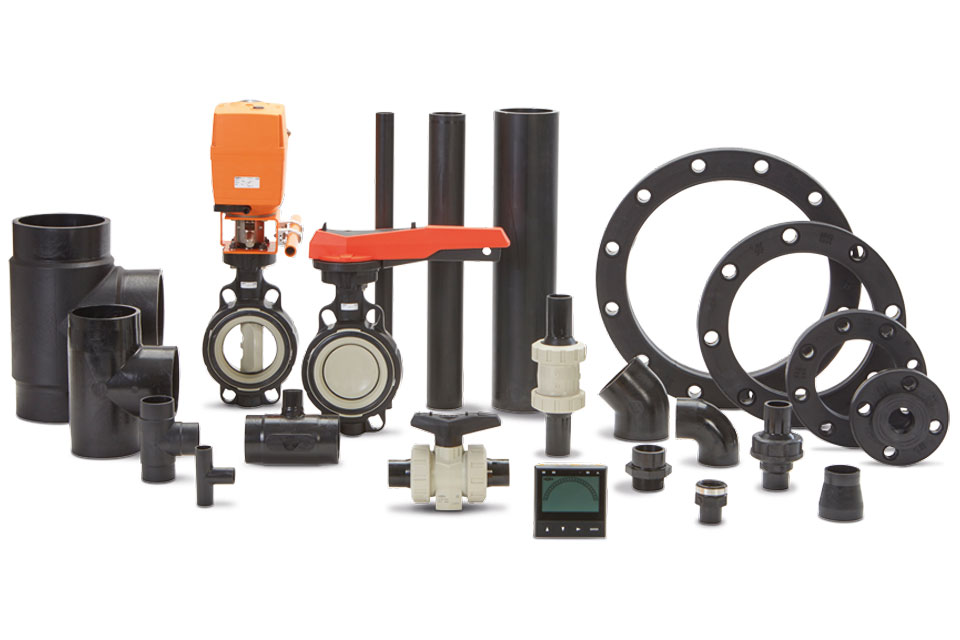

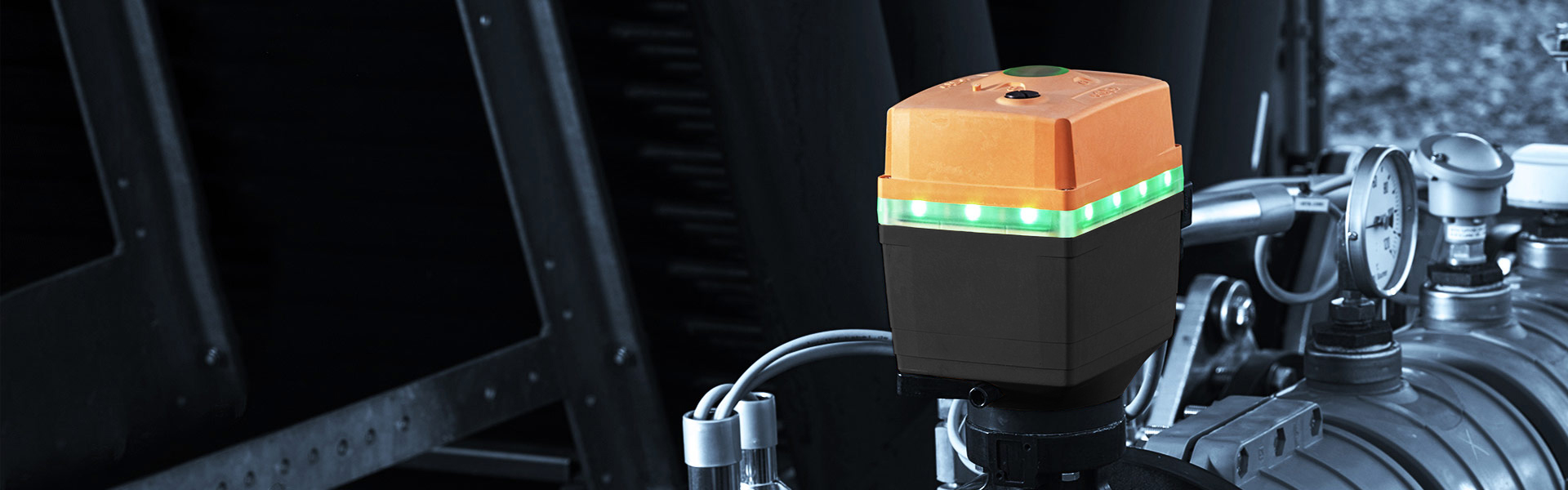

Discover cutting-edge polymer solutions for efficient and sustainable mission-critical data center infrastructure cooling. Explore advanced piping systems to improve your Power Usage Effectiveness (PUE) and Water Usage Effectiveness (WUE) and the reliability of your thermal management solution.

Experience introducing our latest innovation for corrosion-free and leakage-free direct-to-chip cooling, experience live hands-on demonstration of fast and easy jointing technologies for piping systems, and meet our experts live on stage, discussing the future of piping systems in mission-critical infrastructure.