Long-lasting Networks for Fire Fighting

Firefighting lines face a range of challenges. These include maintaining adequate water pressure, ensuring firefighter safety, and addressing aging infrastructure. Additionally, budget limitations for planners and installers, along with the need for a skilled workforce, contribute to the complexity of fire protection efforts. Selecting the right material for underground piping systems in this demanding environment is crucial.

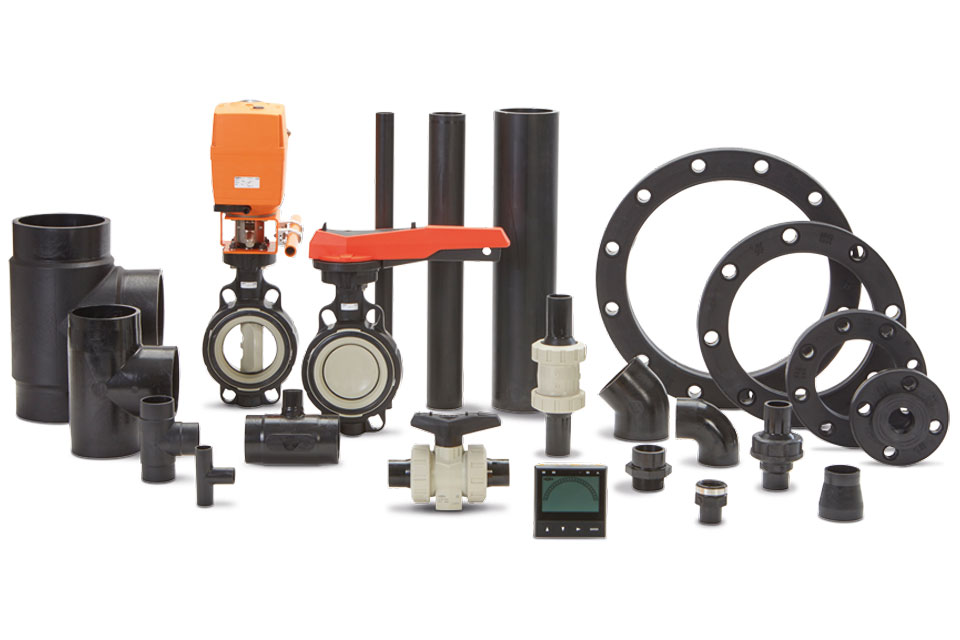

Our FM Polyethylene (PE) system offers the highest level of safety and reliability for firefighting water systems. FM Approvals, an internationally recognized certification organization, rigorously tests and certifies components for fire protection systems. Each of our products with FM Approval meets stringent quality, technical integrity, and performance standards.