Project background

The ELT’s primary mirror will consist of 798 hexagonal segments, with a diameter of approx. 1.5 meters each and made of a glass-ceramic material with very low thermal expansion. In order to achieve the highest possible sensitivity, the segments need to be ecoated every 18 months. This means removing, recoating, and reinstalling two segments every day throughout the ELT’s lifespan. Therefore, when Fagerström was was awarded the contract to design a washing and stripping plant, the company required flow solutions that could ensure a precise and reliable operation while withstanding harsh environments.

Selected technical solution

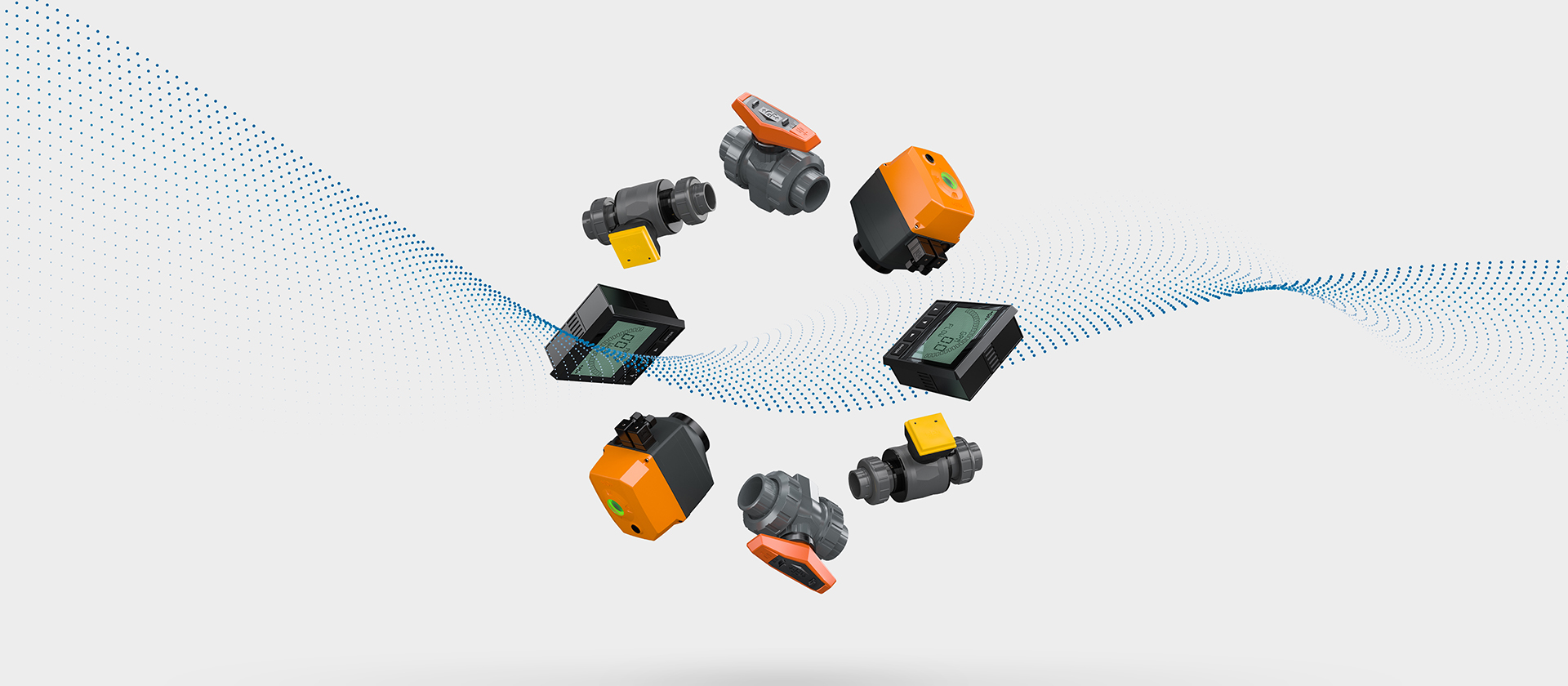

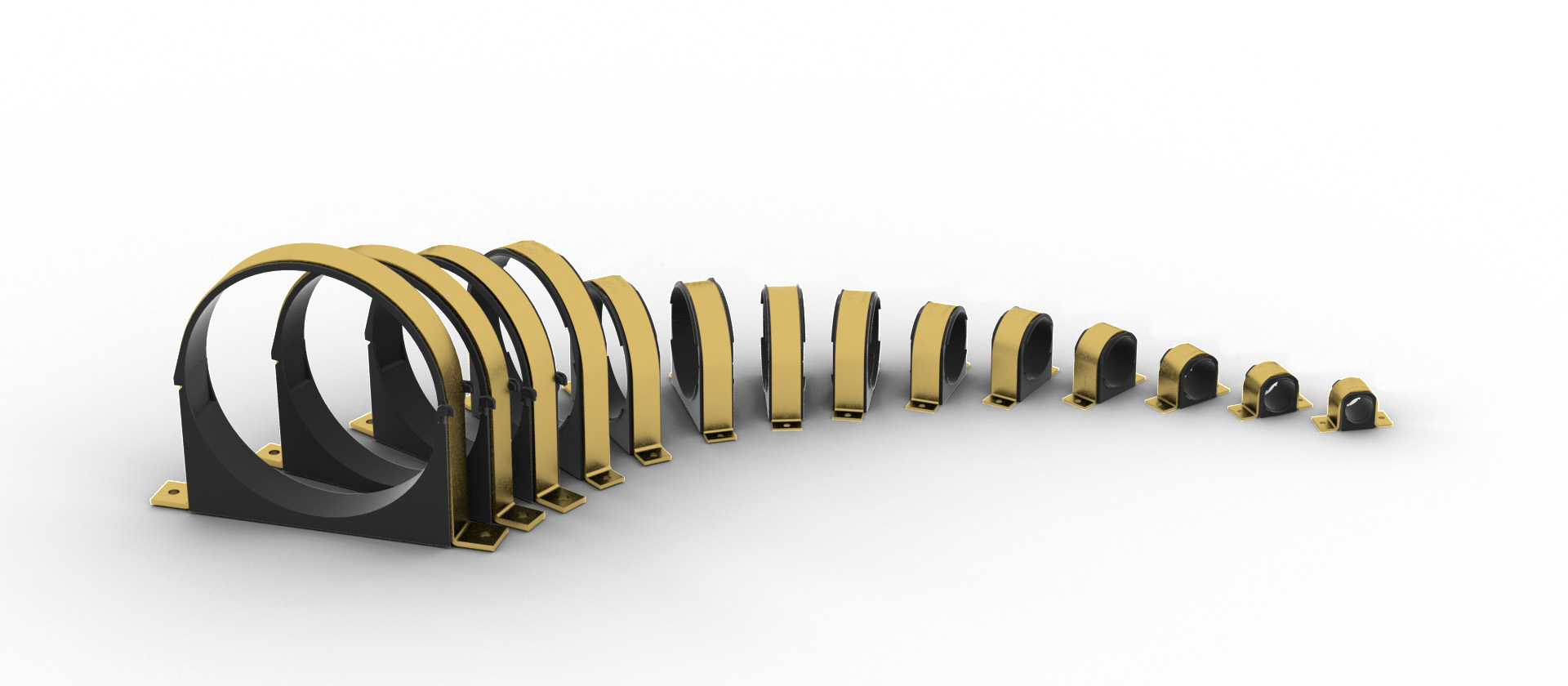

The plant uses sulfuric acid and cerium sulfate to dissolve the reflective layer of the segments, which is primarily made of silver. The segments are washed with ultrapure water. Then, the surface is stripped and dried using an air knife before being recoated. After extensive material testing, GF Piping Systems supplied a complete solution consisting of manual and automated valves from the PROGEF product family as well as accessories such as LED position feedback sensors and spring return units. In addition, the company provided critical measurement sensors for parameters including level, pressure, and temperature.

Achieved improvement

PROGEF is a polypropylene welded piping system designed for durability and high chemical resistance, and therefore contributes to a long-lasting and reliable operation for Fagerström’s washing and stripping plant. At the same time, GF Piping Systems’ measurement sensors optimize compatibility while providing the operators with precise data for this essential process. When the ELT becomes operational at the end of the decade, the plant will play a key role in advancing astrophysical knowledge, enabling a deeper exploration of the Universe and providing sharper images of cosmic objects than ever before.