Water Treatment can be a very challenging market. Vulnerabilities can lay everywhere, and problems can occur without you even knowing them. Starting at the beginning of the planning phase, the selection of the single components, the installation, operation, and maintenance of the plant, GF Piping Systems can support you with personalized solutions for your unique project.

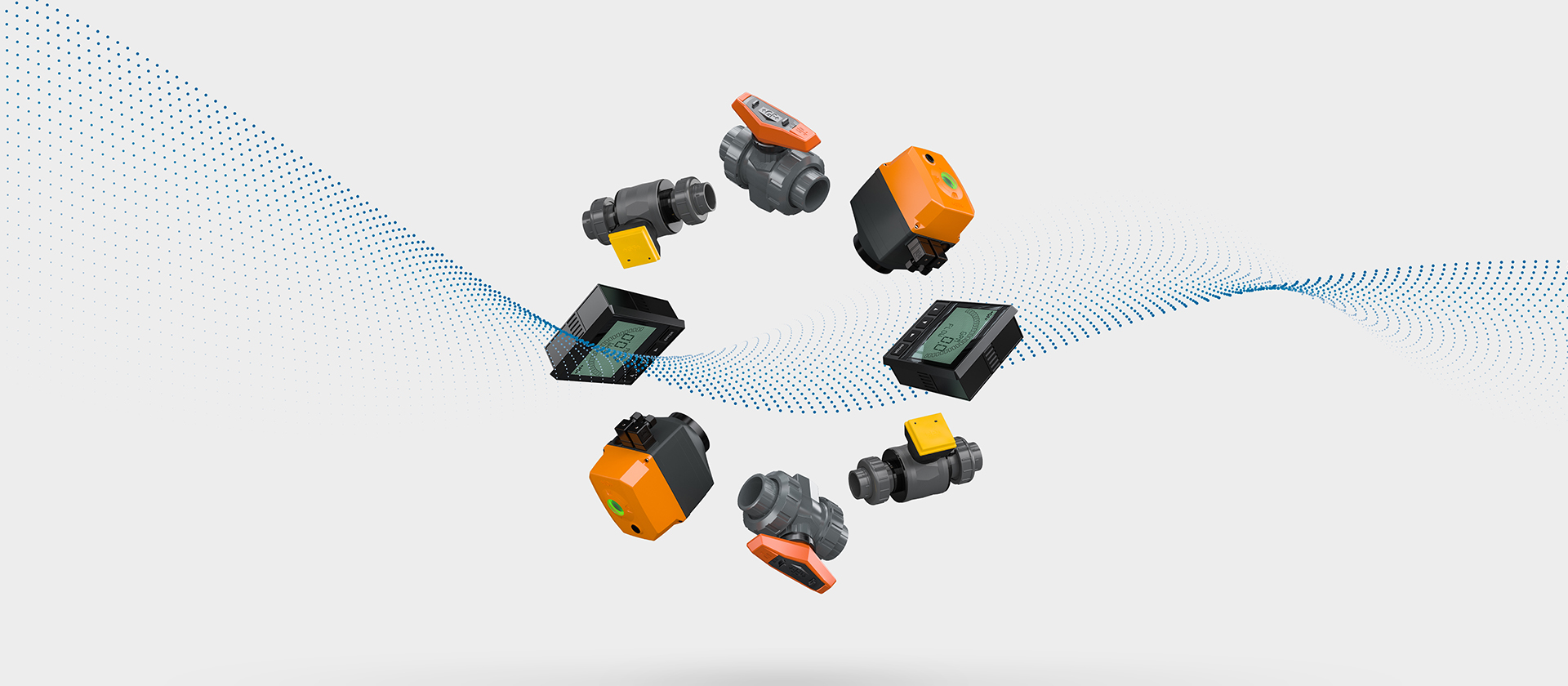

Process Automation

In a digitalized world, everything is connected, and water treatment plants should be too. Analog and independent components hamper media analysis and stretch response times. With our wide range of products, we can close the whole control loop and enable our customers to design, select, install and own customized Process Automation solutions. We are the proven partner for interoperable systems, where our solutions are greater than the sum of its parts. We make Process Automation easy.

Specialized Solutions

There is a seemingly endless list of challenges during the design phase, installing a water treatment plant and its maintenance down the road. With GF Piping Systems and its Specialized Solutions, plant owners and planners can concentrate on their daily business while our experts cover every aspect of a project's process. Specialized Solutions from GF Piping System are the helping hand for customer needs. Being a well-trusted and well-proven partner, we are ready when you are.

Water Treatment

Depending on the application area, our customers face different water treatment process challenges ranging from guaranteeing high water qualities and providing reliable measurements to assuring stringent regulations. We use our know-how and experience to make sure every project is executed at the highest standards to fulfill all the requirements and exceed our customers and society's expectation because water matters - water connects.

Success Stories

Reusing process water in Japan

Water is a link like any other in the production chain when it comes to industrial applications, and it can be an expensive one. With growing demand and limited resources, those costs only go up with time unless you start closing the loop and reusing process water.

Together with a key energy sector industrial player in Japan, GF proved the reuse loop to be cost-competitive against continuing to draw new water from the network. It also had two welcome side effects: better environmental impact, of course, and improved process water quality management and stability over time.

The icing on the cake: GF's solution approach wipes reliability concerns off the table and eases installation and commissioning to eliminate plant downtimes.

Fighting corrosion in Korea

Corrosion caused leakages in a wastewater aeration tank can lead to costly and unpleasant issues. Yet, if diffusion loses on efficiency, bacteria will starve and ultimately die, turning your wastewater treatment useless.

One of our refinery customers in Korea had a chemical-loaded effluent that generated those said corrosion issues. By converting their system to plastics, GF solved the reliability riddle and reduced the system's pressure drop, thus reducing air compressors' load.

GF's solution reduced the installation and maintenance costs by 30%, improving operating costs.

Analyzing chemical dosing in Hong-Kong

One of our customers in Hong Kong put together one of the most advanced water treatment processes, but water quality was slightly lower than expected.

GF Piping Systems thoroughly analyzed the chemical dosing scheme to identify the problem: a special treatment needed special valves. And as those did not exist on the market, GF committed to create and customize them: problem solved in just a couple of weeks.

These specialized and unique products come with the same guarantees and follow-up as any other in the range.

How to use the sun to produce drinking water

By 2025, 1.8 billion people will be living in regions with absolute water scarcity. So, every drop of water will count. What if you could turn any source into drinking water without any need for external energy or network?

That's the design challenge we assisted a Belgian Water Start-Up to overcome. It resulted in a solar-powered compact skidded unit, fully automated. And what GF brought to the table is a rugged, field-proven process automation concept on top of highly reliable components.

Environmental regulations, water scarcity and increasing demand of customers and society for greener and more sustainable solutions are an important set of trends shaping our world. This system serves as a closed loop in a restaurant in Belgium.

Custom product design and prefabrication

A large proportion of the world's wastewater infrastructure was built in the 60s and 70s. After 50 years of operation, those installations are up for renewal to cope with asset lifecycle, population growth, and new regulations.

Yet, many of the buildings remain in excellent state and will be kept. GF Piping Systems can help you to fit new equipment, custom-designed for spaces that are hard to access.

GF Piping System's' world-leading custom product design and prefabrication capabilities also mean every piece of your plant can be preassembled off-site to limit the onsite burden to an absolute minimum.!

Our Specialized Solutions helped to save time and money and increase plant reliability with off-site prefabrication services. Every project is unique, so let us review your project together.