Shaping the future of sustainable aquaculture

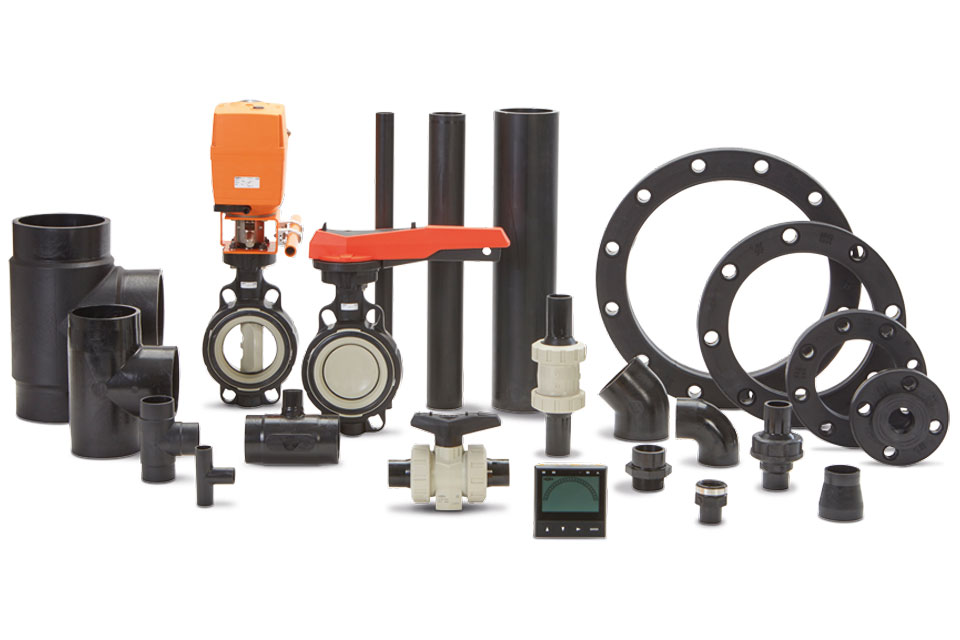

The aquaculture industry is rapidly transitioning towards sustainable practices, shifting from traditional open-water methods to controlled aquatic environments. GF Piping Systems is your trusted partner for innovative and responsible aquaculture solutions. With extensive experience in the field, we offer comprehensive piping, valve, and measurement systems, alongside expert services to support every phase of your project. Our global team empowers the fish farming industry with proven, sustainable technologies that optimize water resource usage, reduce carbon footprints, and minimize environmental impact. By leveraging our industry-leading welding machines and off-site fabrication capabilities, we meet the high demands of large-scale aquaculture projects, customized to meet your challenging specifications.