Energized Partnerships

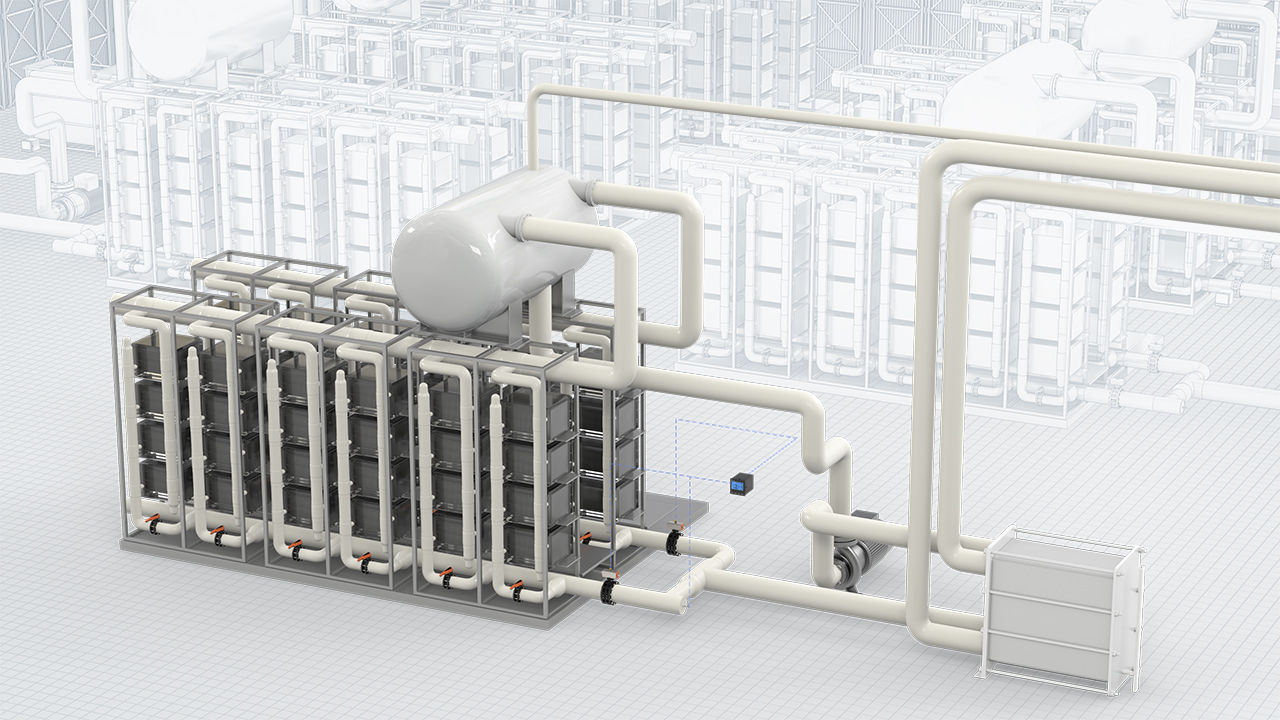

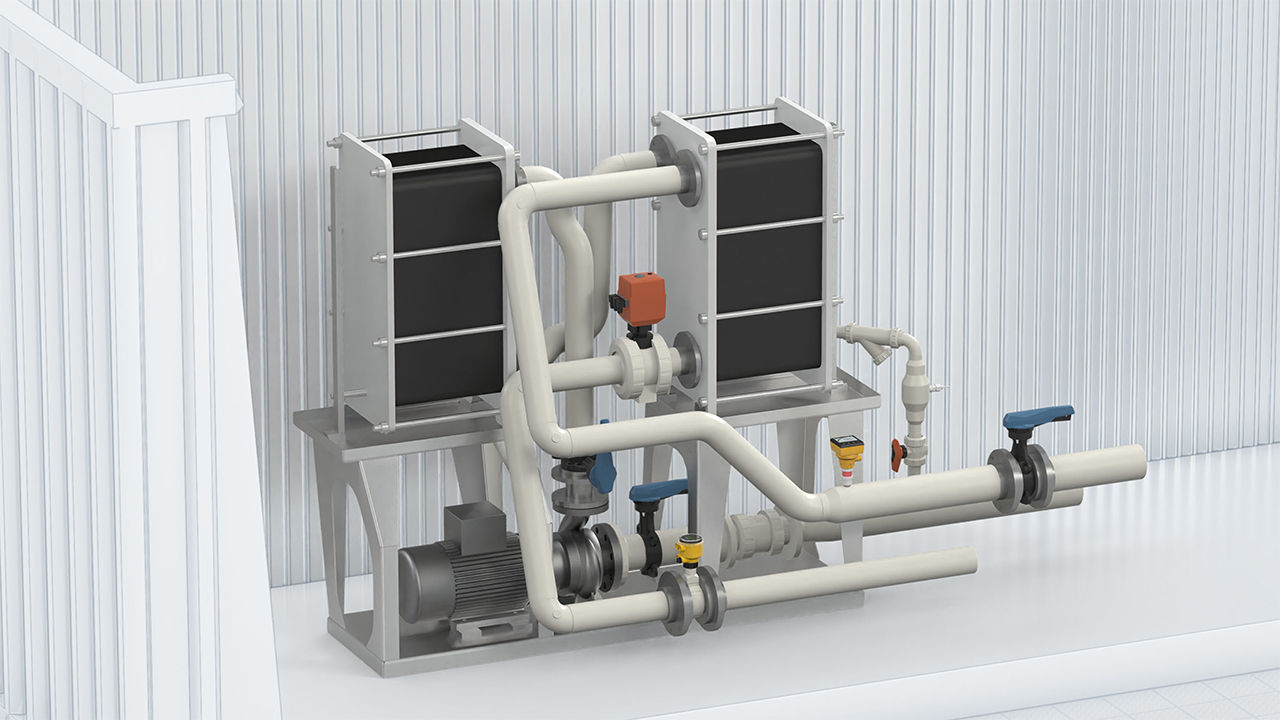

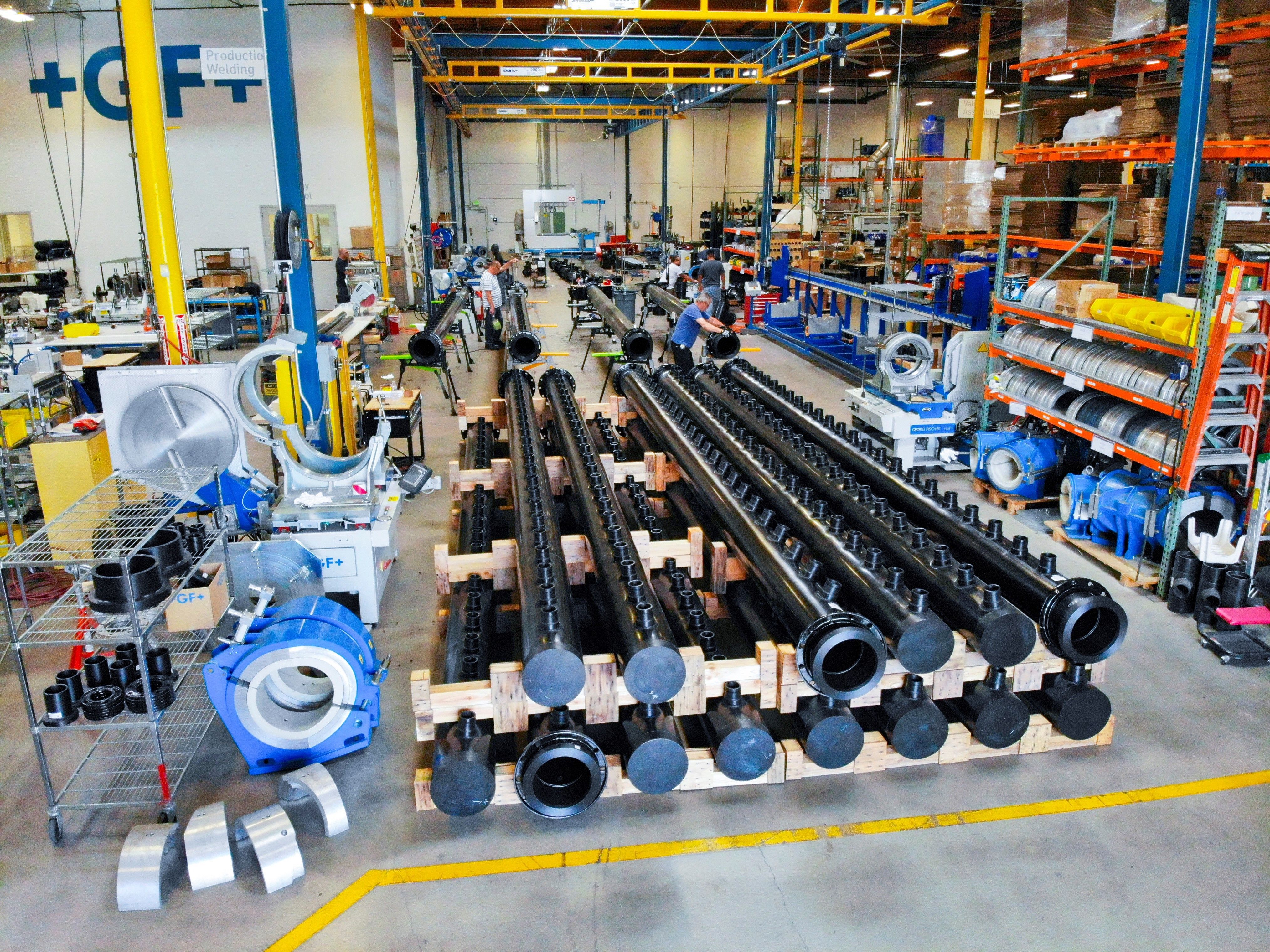

In the accelerating global energy transition, hydrogen has emerged as the potential missing piece to decarbonize even the most difficult-to-abate industries and as a key enabler to reach net zero by 2050. In this transformative energy landscape, GF Piping Systems is your preferred partner for hydrogen projects around the globe as a leading supplier of piping systems for the safe and reliable transport of liquids and gases. With more than 60 years of thermoplastic expertise, we offer corrosion-free polymer solutions across the hydrogen value chain for a seamless and efficient integration into your hydrogen applications.