GF Piping Systems new Pneumatic Actuator is made entirely from plastic, maintenance-free, and has a lifetime as long as the entire piping system. It covers a broad spectrum of valves to suit every need. Thanks to its lighter, more compact design, planning and installation are easier and more efficient. Thanks to the integrated NAMUR interfaces, additional accessories such as Electro-pneumatic Positioners and Solenoid Valves enable end-users to widen the functionality and automation level of the valve assembly. Process Automation, therefore, offers the complete product range as the full solution supplier.

- Electro-pneumatic Positioner for rotary actuators

Precise control: The Electro-pneumatic Positioner was designed and tested for the new Pneumatic Actuator. Enabling 100% system flexibility, quick assembly, and easy commissioning.

- Pneumatic Actuator

The pneumatic actuators are considerably more compact than earlier models and therefore support compact installation with tighter spacing of PP-GF pipes, leaving more space in order to install all necessary components more easily.

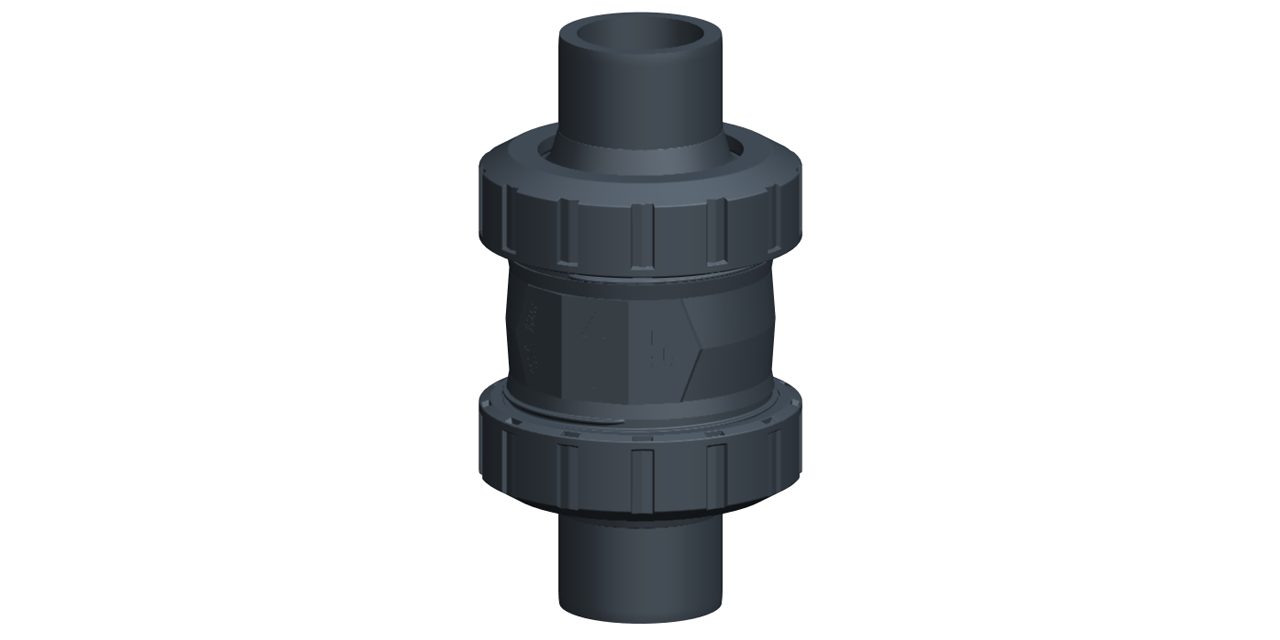

- Ball Valve 546 Pro

Flexible sizing to find the right fit - The new design of the interface between the Ball Valve 546 Pro and the Pneumatic Actuator range enable users to find the right fit in terms of torque and size even in low-pressure applications. Choose from standard configurations or contact GF Piping Systems for customized assemblies.

Please accept all cookies to view the external content.

- Electro-pneumatic Positioner for stroke actuators

Compact top-mount positioner tested and optimized for GF Piping Systems diaphragm valves type DIASTAR.

- Diaphragm valve type DIASTAR

Designed to optimize the flow profile of the liquid inside the pipe, these valves are made entirely of plastic for excellent durability and reliability. The modular design allows them to be easily adapted to process conditions.

Enhancing plant efficiency with digital field connectivity

To enhance plant efficiency, the automation industry is embracing specific trends. These trends include Industry 4.0, implementing connected systems, adopting predictive maintenance practices, and integrating the Industrial Internet of Things (IIoT).

Our Industrial Ethernet connectivity options help to plan flexible networks and commission the devices quickly and easily, including access to all relevant device parameters.

GF Piping System offers Industrial Ethernet for both Electric Actuators and Electro-pneumatic Positioners.

Read more

?qlt=82&wid=960&ts=1710854081570&dpr=on,1&fit=wrap)

Pneumatic Actuator

The new Pneumatic Actuator by GF Piping Systems covers a broad spectrum of valves to suit every need. Thanks to its lighter, more compact design, planning and installation are more accessible and more efficient. The Pneumatic Actuator is protected by a cover made from high-quality and corrosion-free polypropylene (PP-GF) and is supplied in optimal combination with the valve.

Please accept all cookies to view the youtube video content.

All in one solution

The perfect valve pack. The Electro-pneumatic Positioner was tuned and tested with the Pneumatic Actuator and the Ball Valve 546 Pro. Thanks to the perfect alignment, precise flow control becomes simple. Additionally, an auto-tune function ensures quick commissioning. The Pneumatic Actuator and the Electro-pneumatic Positioner are also available for diaphragm valves type DIASTAR.

Please accept all cookies to view the youtube video content.

Further accessories

GF Piping Systems new Electro-pneumatic Positioner line ensures a safe and high-class control and regulation function of all pneumatically actuated valves.

A positioner is not only the connection between the actuator and the process it is the gateway to digitalization. Communication interfaces like PROFINET and EtherNet/IP (Q1/22), and analog and binary feedback ensure state-of-the art integration standards and will lead the way to a digital and process data driven future.

Solenoid pilot valves are used to open and close pneumatic actuated valves by pilot controlling the pneumatic actuators. With these, it is possible to switch large valves with low power and less compressed air, as only a small coil needs to be energized and a small working chamber is filled with compressed air.